Page 125 - GARR_TOOL(CATALOG_INT)

P. 125

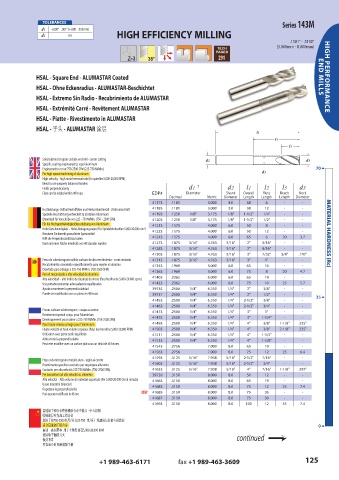

TOLERANCES Series 143M

d1 +.000" –.001" (+.000 –.025mm)

d2 h6 HIGH EFFICIENCY MILLING

.1181" - .3150"

(3.000mm - 8.000mm)

291

38°

HSAL - Square End - ALUMASTAR Coated END MILLS HIGH PERFORMANCE

HSAL - Ohne Eckenradius - ALUMASTAR-Beschichtet

HSAL - Extremo Sin Radio - Recubrimiento de ALUMASTAR

HSAL - Extrémité Carré - Revêtement ALUMASTAR

HSAL - Piatte - Rivestimento in ALUMASTAR

HSAL - 平头 - ALUMASTAR 涂层

平头

涂层

Solid submicron grain carbide end mill - center cutting

Specific coating engineered to repel aluminum

Engineered to run at 750-2500 SFM (225-750 M/Min.) 70 6

For high speed machining of aluminum

High velocity - high metal removal rate (for spindles 5,000-20,000 RPM)

Need to use properly balanced holders

Holds perpendicularity d1 † d2 l1 l2 l3 d3

Flats can be added within 48 hours EDP# Diameter Shank Overall Flute Reach Neck

Decimal Metric Diameter Length Length Length Diameter

41173 .1181 3.000 3.0 38 6 - -

Hochleistungs- Vollhartmetallfräser aus Feinkornhartmetall - Zentrumsschnitt 41183 .1181 3.000 3.0 38 12 - -

Spezielle Beschichtung entwickelt zu abstoßen Aluminium 41193 .1250 1/8" 3.175 1/8" 1-1/2" 1/4" - -

Entwickelt für Vorschübe von 225 - 750 M/Min. (750 – 2500 SFM) 41203 .1250 1/8" 3.175 1/8" 1-1/2" 1/2" - -

Für die Hochgeschwindigkeitsbearbeitung von Aluminium 41213 .1575 4.000 6.0 50 8 - -

Hohe Geschwindigkeit – Hohe Abtragungsraten (Für Spindeldrehzahlen 5.000-20.000 min -1 )

Benutzen Sie korrekt gewuchtete Spannmittel 41223 .1575 4.000 6.0 50 12 - - MATERIAL HARDNESS (Rc)

Hilft die Perpendicularität zu halten 41243 .1575 4.000 6.0 65 6 20 3.7

Kann mit einer Fläche innerhalb von 48 Stunden warden 41273 .1875 3/16" 4.763 3/16" 2" 5/16" - -

41283 .1875 3/16" 4.763 3/16" 2" 9/16" - -

41303 .1875 3/16" 4.763 3/16" 3" 7/32" 3/4" .170"

Fresa de submicrograno sólido carburo de alto rendimiento - corte centrado 41313 .1875 3/16" 4.763 3/16" 3" 1" - -

Recubrimiento concebido específicamente para repeler el aluminio 41343 .1969 5.000 6.0 65 16 - -

Diseñado para trabajar a 225-750 M/Min. (750-2500 SFM) 41363 .1969 5.000 6.0 75 8 20 4.7

Para el mecanizado a alta velocidad de aluminio

Alta velocidad – alto índice de desalojo de viruta (Para husillos de 5.000-20.000 r.p.m.) 41403 .2362 6.000 6.0 65 19 - -

Use portaherramientas adecuadaente equilibrados 41423 .2362 6.000 6.0 75 10 25 5.7

Ayuda a mantener la perpendicularidad 39735 .2500 1/4" 6.350 1/4" 2" 3/8" - -

Puede ser modificado con un plano en 48 horas 39737 .2500 1/4" 6.350 1/4" 2" 1/2" - - 35

41453 .2500 1/4" 6.350 1/4" 2-1/2" 3/8" - - 6

41463 .2500 1/4" 6.350 1/4" 2-1/2" 3/4" - -

Fraises carbure submicrograin - coupe au centre 41473 .2500 1/4" 6.350 1/4" 3" 1" - -

Revetement special conçu pour l’aluminium

Developpement pour usiner a 225-750 M/Min. (750-2500 SFM) 41475 .2500 1/4" 6.350 1/4" 3" 1-1/4" - -

Pour haute vitesse usinage pour l’aluminium 41493 .2500 1/4" 6.350 1/4" 4" 3/8" 1-1/8" .235"

Haute velocite et haut volume copeaux (Pour les mandrins 5,000-20,000 RPM) 41503 .2500 1/4" 6.350 1/4" 4" 3/8" 2-1/8" .235"

Utilisation avec porte outils équilibrés 41511 .2500 1/4" 6.350 1/4" 4" 1-1/2" - -

Aide a tenir la perpendicularite 41513 .2500 1/4" 6.350 1/4" 4" 1-5/8" - -

Peut etre modifier avec un surface plat sous un delai de 48 heures

41543 .2756 7.000 8.0 65 19 - -

41563 .2756 7.000 8.0 75 12 25 6.4

41593 .3125 5/16" 7.938 5/16" 2-1/2" 7/16" - -

Fresa sub-micrograno metallo duro - taglio al centro

Rivestimento specifico costruito per respingere alluminio 41603 .3125 5/16" 7.938 5/16" 2-1/2" 3/4" - -

Costruito per alta velocità 225-750 M/Min. (750-2500 SFM) 41623 .3125 5/16" 7.938 5/16" 4" 7/16" 1-1/8" .297"

Per lavorazioni ad alta velocità su alluminio 39739 .3150 8.000 8.0 50 12 - -

Alta velocità - Alto volume di materiale asportato (Per 5.000-20.000 Giri al minuto) 41663 .3150 8.000 8.0 65 19 - -

Usare mandrini bilanciati 41683 .3150 8.000 8.0 75 12 25 7.4

Rispettare la perpendicolarità

Può essere modificata in 48 ore NEW 41685 .3150 8.000 8.0 75 26 - -

41687 .3150 8.000 8.0 75 30 - -

41693 .3150 8.000 8.0 100 12 55 7.4

高速加工铝合金整体硬质合金立铣刀 - 中心切削

特殊涂层专为加工铝合金

适用于按750-2500英尺/分(225-750 米/分) 线速度运转的专用涂层

适合高速加工铝合金 0 6

高速—高切屑率 用于主轴转速在5,000-20,000 RPM

使用动平衡的刀夹 continued ?

保持垂直

可在48小时内磨成削平柄

+1 989-463-6171 fax +1 989-463-3609 125