Page 282 - GARR_TOOL(CATALOG_INT)

P. 282

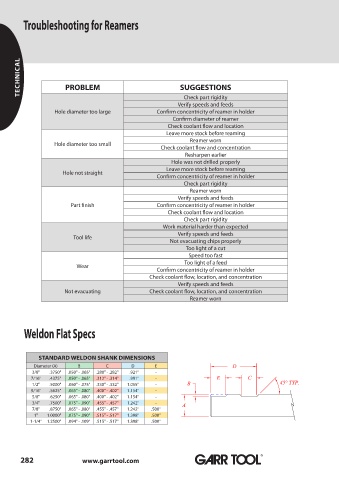

Troubleshooting for Reamers

TECHNICAL PROBLEM SUGGESTIONS

Check part rigidity

Verify speeds and feeds

Hole diameter too large Confirm concentricity of reamer in holder

Confirm diameter of reamer

Check coolant flow and location

Leave more stock before reaming

Reamer worn

Hole diameter too small

Check coolant flow and concentration

Resharpen earlier

Hole was not drilled properly

Leave more stock before reaming

Hole not straight

Confirm concentricity of reamer in holder

Check part rigidity

Reamer worn

Verify speeds and feeds

Part finish Confirm concentricity of reamer in holder

Check coolant flow and location

Check part rigidity

Work material harder than expected

Verify speeds and feeds

Tool life

Not evacuating chips properly

Too light of a cut

Speed too fast

Too light of a feed

Wear

Confirm concentricity of reamer in holder

Check coolant flow, location, and concentration

Verify speeds and feeds

Not evacuating Check coolant flow, location, and concentration

Reamer worn

Weldon Flat Specs

STANDARD WELDON SHANK DIMENSIONS

Diameter (A) B C D E

3/8" .3750" .050" - .065" .280" - .282" .921" -

7/16" .4375" .050" - .065" .312" - .314" .991" -

1/2" .5000" .060" - .075" .330" - .332" 1.055" -

9/16" .5625" .065" - .080" .400" - .402" 1.154" -

5/8" .6250" .065" - .080" .400" - .402" 1.154" -

3/4" .7500" .075" - .090" .455" - .457" 1.242" -

7/8" .8750" .065" - .080" .455" - .457" 1.242" .500"

1" 1.0000" .075" - .090" .515" - .517" 1.398" .500"

1-1/4" 1.2500" .094" - .109" .515" - .517" 1.398" .500"

282 www.garrtool.com ®