Page 281 - GARR_TOOL(CATALOG_INT)

P. 281

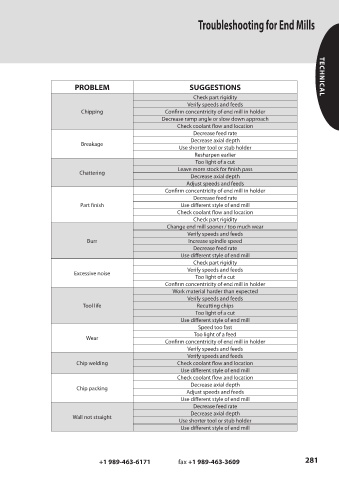

Troubleshooting for End Mills

PROBLEM SUGGESTIONS TECHNICAL

Check part rigidity

Verify speeds and feeds

Chipping Confirm concentricity of end mill in holder

Decrease ramp angle or slow down approach

Check coolant flow and location

Decrease feed rate

Decrease axial depth

Breakage

Use shorter tool or stub holder

Resharpen earlier

Too light of a cut

Leave more stock for finish pass

Chattering

Decrease axial depth

Adjust speeds and feeds

Confirm concentricity of end mill in holder

Decrease feed rate

Part finish Use different style of end mill

Check coolant flow and location

Check part rigidity

Change end mill sooner / too much wear

Verify speeds and feeds

Burr Increase spindle speed

Decrease feed rate

Use different style of end mill

Check part rigidity

Verify speeds and feeds

Excessive noise

Too light of a cut

Confirm concentricity of end mill in holder

Work material harder than expected

Verify speeds and feeds

Tool life Recutting chips

Too light of a cut

Use different style of end mill

Speed too fast

Too light of a feed

Wear

Confirm concentricity of end mill in holder

Verify speeds and feeds

Verify speeds and feeds

Chip welding Check coolant flow and location

Use different style of end mill

Check coolant flow and location

Decrease axial depth

Chip packing

Adjust speeds and feeds

Use different style of end mill

Decrease feed rate

Decrease axial depth

Wall not straight

Use shorter tool or stub holder

Use different style of end mill

+1 989-463-6171 fax +1 989-463-3609 281