Page 280 - GARR_TOOL(CATALOG_INT)

P. 280

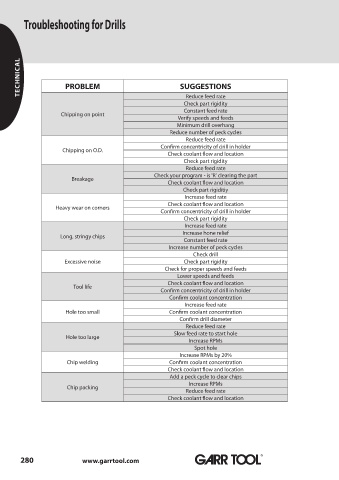

Troubleshooting for Drills

TECHNICAL PROBLEM SUGGESTIONS

Reduce feed rate

Check part rigidity

Constant feed rate

Chipping on point

Verify speeds and feeds

Minimum drill overhang

Reduce number of peck cycles

Reduce feed rate

Confirm concentricity of drill in holder

Chipping on O.D.

Check coolant flow and location

Check part rigidity

Reduce feed rate

Check your program - is 'R' clearing the part

Breakage

Check coolant flow and location

Check part rigiditiy

Increase feed rate

Check coolant flow and location

Heavy wear on corners

Confirm concentricity of drill in holder

Check part rigidity

Increase feed rate

Increase hone relief

Long, stringy chips

Constant feed rate

Increase number of peck cycles

Check drill

Excessive noise Check part rigidity

Check for proper speeds and feeds

Lower speeds and feeds

Check coolant flow and location

Tool life

Confirm concentricity of drill in holder

Confirm coolant concentration

Increase feed rate

Hole too small Confirm coolant concentration

Confirm drill diameter

Reduce feed rate

Slow feed rate to start hole

Hole too large

Increase RPMs

Spot hole

Increase RPMs by 20%

Chip welding Confirm coolant concentration

Check coolant flow and location

Add a peck cycle to clear chips

Increase RPMs

Chip packing

Reduce feed rate

Check coolant flow and location

280 www.garrtool.com ®