Page 135 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 135

USER GUIDE

• DR-DH drills can be used with any type of adaptation. Double-ended Pad

However, concentric adapters such as hydraulic chucks Worn support pads provide poor surface finish in a drilled

are advantageous for better runout. When machining hole. In this case, pads should be rotated or replaced. INDEXABLE DRILLS

high temperature alloys or applying very high machining

loads, it is advisable to use strong gripping adapters Rotate when wear shows on the back side of the pad

such as: side lock adapters, power / hydraulic chucks.

• In case of chip formation or chip evacuation problems,

the following sequence is recommended:

1 Reduce cutting speed by 10%

2 Increase internal coolant pressure

3 Apply a pecking cycle

4 Interrupted cut will have a direct influence on

hole accuracy, quality and drill life. (Sometimes

even tool breakage can occur).

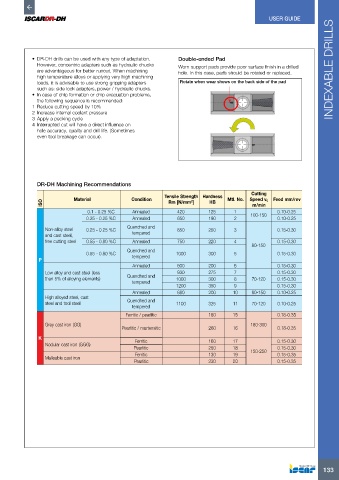

DR-DH Machining Recommendations

Cutting

Tensile Strength Hardness Mtl. No. Speed vc Feed mm/rev

Condition

Material

ISO Rm [N/mm ] HB m/min

2

0.1 - 0.25 %C Annealed 420 125 1 0.10-0.25

0.25 - 0.25 %C Annealed 650 190 2 100-150 0.10-0.25

Non-alloy steel 0.25 - 0.25 %C Quenched and 850 250 3 0.15-0.30

and cast steel, tempered

free cutting steel 0.55 - 0.80 %C Annealed 750 220 4 0.15-0.30

80-150

Quenched and

0.55 - 0.80 %C 1000 300 5 0.15-0.30

P tempered

Annealed 600 200 6 0.15-0.30

Low alloy and cast steel (less 930 275 7 0.15-0.30

than 5% of alloying elements) Quenched and 1000 300 8 70-120 0.15-0.30

tempered

1200 350 9 0.15-0.30

Annealed 680 200 10 80-150 0.10-0.25

High alloyed steel, cast

steel and tool steel Quenched and 1100 325 11 70-120 0.10-0.25

tempered

Ferritic / pearlitic 180 15 0.18-0.35

Grey cast iron (GG) 180-300

Pearlitic / martensitic 260 16 0.18-0.35

K Ferritic 160 17 0.15-0.30

Nodular cast iron (GGG)

Pearlitic 250 18 0.15-0.30

Ferritic 130 19 150-250 0.15-0.35

Malleable cast iron

Pearlitic 230 20 0.15-0.35

133