Page 140 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 140

USER GUIDE

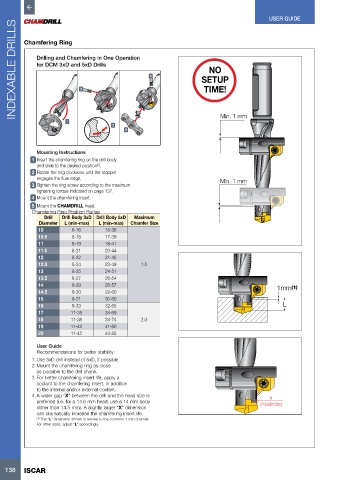

INDEXABLE DRILLS Drilling and Chamfering in One Operation 4 SETUP

Chamfering Ring

for DCM 3xD and 5xD Drills

NO

TIME!

3

1 Min. 1 mm

2

5

Mounting Instructions

1 Insert the chamfering ring on the drill body

and slide to the desired position .

(1)

2 Rotate the ring clockwise until the stopper

engages the flute edge. Min. 1 mm

3 Tighten the ring screw according to the maximum

tightening torque indicated on page 137.

4 Mount the chamfering insert.

5 Mount the CHAMDRILL head.

Chamfering Ring Position Range

Drill Drill Body 3xD Drill Body 5xD Maximum

Diameter L (min-max) L (min-max) Chamfer Size

10 8-16 15-36

10.5 8-18 17-39

11 8-19 18-41

11.5 8-21 20-44

12 8-22 21-46

12.5 8-24 23-49 1.5

13 8-25 24-51

13.5 8-27 26-54

14 9-29 28-57 1mm (1)

14.5 9-30 29-60

15 9-31 30-60

16 9-33 32-65 L

17 11-35 34-69

18 11-38 34-74 2.0

19 11-42 41-80

20 11-45 44-85

User Guide

Recommendations for better stability:

1 Use 3xD drill instead of 5xD, if possible.

2 Mount the chamfering ring as close

as possible to the drill shank.

3 For better chamfering insert life, apply a

coolant to the chamfering insert, in addition

to the internal and/or external coolant.

4 A wider gap “X” between the drill and the head size is X

preferred (i.e. for a 14.6 mm head, use a 14 mm body (maximize)

rather than 14.5 mm). A slightly larger “X” dimension

can dramatically increase the chamfering insert life.

(1) The “L” dimension shown is relative to the common 1 mm chamfer.

For other sizes, adjust “L” accordingly.

138 ISCAR