Page 200 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 200

USER GUIDE

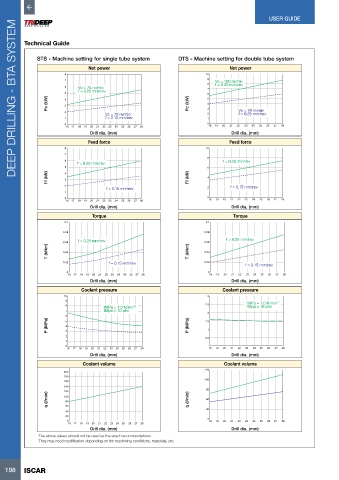

DEEP DRILLING - BTA SYSTEM

Technical Guide

STS - Machine setting for single tube system DTS - Machine setting for double tube system

Net power Net power

8 10

9

7 Vc = 100 m/min

8 f = 0.25 mm/rev

6 Vc = 75 m/min

f = 0.25 mm/rev 7

5 6

Pc (kW) 4 3 Pc (kW) 5 4

2 3 Vc = 70 m/min

Vc = 75 m/min 2 f = 0.25 mm/rev

1 f = 0.15 mm/rev 1

0 0 18 19 20 21 22 23 24 25 26 27 28

16 17 18 19 20 21 22 23 24 25 26 27 28

Drill dia. (mm) Drill dia. (mm)

Feed force Feed force

8 10

7

8

6 f = 0.25 mm/rev

f = 0.25 mm/rev

5 6

Ff (kN) 4 3 Ff (kN) 4

2 f = 0.15 mm/rev

f = 0.15 mm/rev 2

1

0

0 18 19 20 21 22 23 24 25 26 27 28

16 17 18 19 20 21 22 23 24 25 26 27 28

Drill dia. (mm) Drill dia. (mm)

Torque Torque

0.1 0.1

0.08 0.08

f = 0.25 mm/rev f = 0.25 mm/rev

0.06 0.06

T (kNm) 0.04 T (kNm) 0.04

f = 0.15 mm/rev f = 0.15 mm/rev

0.02 0.02

0 0

16 17 18 19 20 21 22 23 24 25 26 27 28 18 19 20 21 22 23 24 25 26 27 28

Drill dia. (mm) Drill dia. (mm)

Coolant pressure Coolant pressure

10 3

9 1MPa = 1.0 N/mm 2

2.5

8 2 1Mpa ≈ 10 atm

1MPa = 1.0 N/mm

7 1Mpa ≈ 10 atm

2

6

P (MPa) 5 4 3 P (MPa) 1.5 1

2

0.5

1

0

16 17 18 19 20 21 22 23 24 25 26 27 28 18 19 20 21 22 23 24 25 26 27 28

Drill dia. (mm) Drill dia. (mm)

Coolant volume Coolant volume

120

200

180

100

160

140

80

120

q (l/min) 100 q (l/min) 60

80

60

40

40

20

0

0 18 19 20 21 22 23 24 25 26 27 28

16 17 18 19 20 21 22 23 24 25 26 27 28

Drill dia. (mm) Drill dia. (mm)

The above values should not be used as the exact recommendations.

They may need modification depending on the machining conditions, materials, etc.

198 ISCAR