Page 266 - ISCAR(MILLINGCATALOG 38_2021)

P. 266

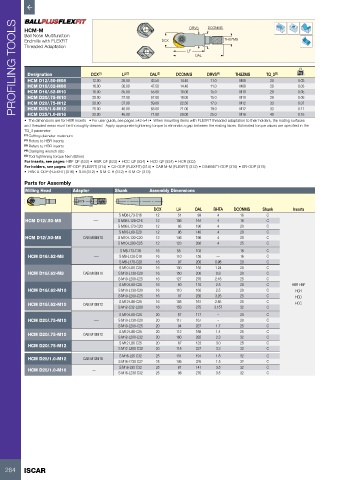

PROFILING TOOLS HCM-M DCX (1) 26.00 OAL (3) DCX DCONMS OAL DRVS (4) THSZMS M08 TQ_3 (5) kg

DCONMS

DRVS

Ball Nose Multifunction

Endmills with FLEXFIT

Threaded Adaptation

LF

(2)

Designation

THSZMS

LF

HCM D12/.50-M08

0.03

14.40

12.00

43.50

20

11.0

HCM D16/.62-M08

47.50

11.0

M08

20

16.00

0.03

14.40

30.00

HCM D16/.62-M10

18.00

35.00

M10

0.05

55.00

16.00

15.0

29

20.00

29

15.0

M10

0.06

37.00

HCM D20/.75-M10

57.00

18.00

37.00

22.50

17.0

M12

59.00

33

HCM D20/.75-M12

0.07

20.00

21.00

19.0

25.00

46.00

68.00

0.11

HCM D25/1.0-M12

M12

33

71.00

46.00

HCM D25/1.0-M16

0.16

25.0

29.00

40

M16

25.00

• The dimensions are for HBR inserts • For user guide, see pages 542-547• When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces

and threaded areas must be thoroughly cleaned. Apply appropriate tightening torque to eliminate a gap between the mating faces. Estimated torque values are specified in the

TQ_3 parameter

(1) Cutting diameter maximum

(2) Refers to HBR inserts

(3) Refers to HBR inserts

(4) Clamping wrench size

(5) Tool tightening torque Nxm (lbfxin)

For inserts, see pages: HBF-QF (533) • HBR-QF (533) • HCC-QF (534) • HCD-QF (534) • HCR (533)

For holders, see pages: BT-ODP (FLEXFIT) (314) • C#-ODP (FLEXFIT) (314) • CAB M-M (FLEXFIT) (312) • DIN69871-ODP (315) • ER-ODP (315)

• HSK A-ODP (FLEXFIT) (316) • S M (312) • S M-C-H (312) • S M-CF (313)

Parts for Assembly

Milling Head Adapter Shank Assembly Dimensions

DCX LH OAL BHTA DCONMS Shank Inserts

S M08-L73-C16 12 51 99 4 16 C

HCM D12/.50-M8 –— S M08-L128-C16 12 106 154 4 16 C

S M08-L170-C20 12 93 196 4 20 C

S M10-L80-C20 12 96 146 4 20 C

HCM D12/.50-M8 CAB M08M10 S M10-L130-C20 12 146 196 4 20 C

S M10-L200-C25 12 123 266 4 25 C

S M8-L73-C16 16 55 103 — 16 C

HCM D16/.62-M8 –— S M8-L128-C16 16 110 158 — 16 C

S M8-L170-C20 16 97 200 0.96 20 C

S M10-L80-C20 16 100 150 1.24 20 C

HCM D16/.62-M8 CAB M08M10 S M10-L130-C20 16 150 200 0.8 20 C

S M10-L200-C25 16 127 270 2.16 25 C

S M10-L80-C20 16 60 110 2.5 20 C HBR HBF

HCM D16/.62-M10 S M10-L130-C20 16 110 160 2.5 20 C HCR

S M10-L200-C25 16 87 230 3.26 25 C HCD

S M12-L86-C25 16 105 161 2.65 25 C

HCM D16/.62-M10 CAB M10M12 HCC

S M12-C32-L200 16 153 275 3.157 32 C

S M10-L80-C20 20 67 117 – 20 C

HCM D20/.75-M10 –— S M10-L130-C20 20 117 167 – 20 C

S M10-L200-C25 20 94 237 1.7 25 C

S M12-L86-C25 20 112 168 1.4 25 C

HCM D20/.75-M10 CAB M10M12

S M12-L200-C32 20 160 282 2.3 32 C

S M12-L86-C25 20 67 123 3.0 25 C

HCM D20/.75-M12 –—

S M12-L200-C32 20 115 237 3.3 32 C

S M16-L95 C32 25 131 191 1.8 32 C

HCM D25/1.0-M12 CAB M12M16

S M16-L230 C32 25 146 326 1.5 32 C

S M16-L95 C32 25 81 141 3.5 32 C

HCM D25/1.0-M16 —

S M16-L230 C32 25 96 276 3.5 32 C

264 ISCAR