Page 275 - ISCAR(MILLINGCATALOG 38_2021)

P. 275

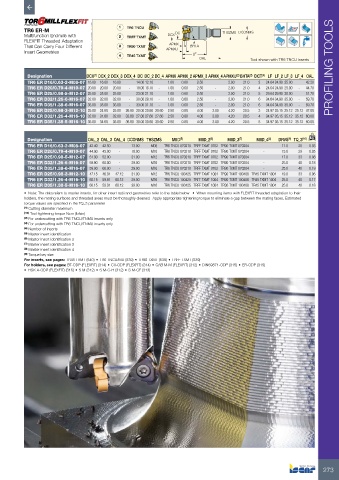

1 TR6 TNCU

TR6 ER-M THSZMS DCONMS

Multifunction Endmills with 2 TRFF TXMT DCX DC

FLEXFIT Threaded Adaptation APMX

That Can Carry Four Different 3 TR90 TXMT APMXU BHTA

Insert Geometries

4 TR45 TXMT LF

OAL Tool shown with TR6 TNCU inserts

(3)

(1)

(2)

Designation DCX DCX_2 DCX_3 DCX_4 DC DC_2 DC_4 APMX APMX_2 APMX_3 APMX_4 APMXU BHTA CICT (4) LF LF_2 LF_3 LF_4 OAL PROFILING TOOLS

TR6 ER D16/0.63-2-M08-07 16.00 16.00 16.00 - 14.00 12.10 - 1.00 0.60 2.50 - 2.00 21.0 2 24.64 24.90 25.00 - 42.20

TR6 ER D20/0.79-4-M10-07 20.00 20.00 20.00 - 18.00 16.10 - 1.00 0.60 2.50 - 2.00 21.0 4 24.64 24.90 25.00 - 44.70

TR6 ER D25/0.98-5-M12-07 25.00 25.00 25.00 - 23.00 21.10 - 1.00 0.60 2.50 - 2.00 21.0 5 29.64 29.90 30.00 - 51.70

TR6 ER D32/1.26-6-M16-07 32.00 32.00 32.00 - 30.00 28.10 - 1.00 0.60 2.50 - 2.00 21.0 6 34.64 34.90 35.00 - 59.70

TR6 ER D35/1.38-6-M16-07 35.00 35.00 35.00 - 33.00 31.10 - 1.00 0.60 2.50 - 2.00 21.0 6 34.64 34.90 35.00 - 59.70

TR6 ER D25/0.98-3-M12-10 25.00 24.60 25.00 26.80 20.00 20.60 20.60 2.50 0.80 4.00 3.00 4.20 20.5 3 24.97 25.15 25.12 25.12 47.00

TR6 ER D32/1.26-4-M16-10 32.00 31.60 32.00 33.80 27.00 27.60 27.60 2.50 0.80 4.00 3.00 4.20 20.5 4 34.97 35.15 35.12 35.12 60.00

TR6 ER D35/1.38-5-M16-10 35.00 34.60 35.00 36.80 30.00 30.60 30.60 2.50 0.80 4.00 3.00 4.20 20.5 5 34.97 35.15 35.12 35.12 60.00

Designation OAL_2 OAL_3 OAL_4 DCONMS THSZMS MIID (5) MIID_2 (6) MIID_3 (7) MIID_4 (8) DRVS (9) TQ_3 (10) kg

TR6 ER D16/0.63-2-M08-07 42.40 42.50 - 13.00 M08 TR6 TNCU 070210 TRFF TXMT 0702 TR90 TXMT 070204 - 11.0 20 0.03

TR6 ER D20/0.79-4-M10-07 44.90 45.00 - 18.00 M10 TR6 TNCU 070210 TRFF TXMT 0702 TR90 TXMT 070204 - 15.0 29 0.05

TR6 ER D25/0.98-5-M12-07 51.90 52.00 - 21.00 M12 TR6 TNCU 070210 TRFF TXMT 0702 TR90 TXMT 070204 - 17.0 33 0.08

TR6 ER D32/1.26-6-M16-07 59.90 60.00 - 29.00 M16 TR6 TNCU 070210 TRFF TXMT 0702 TR90 TXMT 070204 - 25.0 40 0.18

TR6 ER D35/1.38-6-M16-07 59.90 60.00 - 29.00 M16 TR6 TNCU 070210 TRFF TXMT 0702 TR90 TXMT 070204 - 25.0 40 0.19

TR6 ER D25/0.98-3-M12-10 47.15 46.91 47.12 21.00 M12 TR6 TNCU 100425 TRFF TXMT 1004 TR90 TXMT 100408 TR45 TXMT 1004 19.0 33 0.06

TR6 ER D32/1.26-4-M16-10 60.15 59.91 60.12 29.00 M16 TR6 TNCU 100425 TRFF TXMT 1004 TR90 TXMT 100408 TR45 TXMT 1004 25.0 40 0.17

TR6 ER D35/1.38-5-M16-10 60.15 59.91 60.12 29.00 M16 TR6 TNCU 100425 TRFF TXMT 1004 TR90 TXMT 100408 TR45 TXMT 1004 25.0 40 0.18

• Note: The data refers to master inserts, for other insert radii and geometries refer to the table below • When mounting items with FLEXFIT threaded adaptation to their

holders, the mating surfaces and threaded areas must be thoroughly cleaned. Apply appropriate tightening torque to eliminate a gap between the mating faces. Estimated

torque values are specified in the TQ_3 parameter

(1) Cutting diameter maximum

(10) Tool tightening torque Nxm (lbfxin)

(2) For undercutting with TR6 TNCU/TNMU inserts only

(3) For undercutting with TR6 TNCU/TNMU inserts only

(4) Number of inserts

(5) Master insert identification

(6) Master insert identification 2

(7) Master insert identification 3

(8) Master insert identification 4

(9) Torque key size

For inserts, see pages: TR45 TXMT (540) • TR6 TNCU/MU (539) • TR90 TXMT (539) • TRFF TXMT (539)

For holders, see pages: BT-ODP (FLEXFIT) (314) • C#-ODP (FLEXFIT) (314) • CAB M-M (FLEXFIT) (312) • DIN69871-ODP (315) • ER-ODP (315)

• HSK A-ODP (FLEXFIT) (316) • S M (312) • S M-C-H (312) • S M-CF (313)

273