Page 347 - ISCAR(TURNING-CATALOG-42-2022)

P. 347

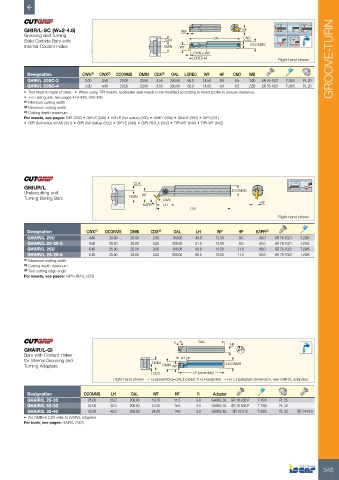

GHIR/L-SC (W=2-4.8) WB HF

Grooving and Turning OAL CND

Solid Carbide Bars with CDX

Internal Coolant Holes DMIN WF DCONMS

CWN-CWX

LDRED Right-hand shown GROOVE-TURN

Designation CWN (1) CWX (2) DCONMS DMIN CDX (3) OAL LDRED WF HF CND WB

GHIR/L 20SC-3 2.00 3.50 20.00 20.00 4.50 200.00 60.0 14.50 9.0 8.5 1.60 SR 76-1021 T-20/5 PL 20

GHIR/L 20SC-4 3.00 4.80 20.00 20.00 4.50 200.00 60.0 14.50 9.0 8.5 2.60 SR 76-1021 T-20/5 PL 20

• Tool head is made of steel. • When using TIPI inserts, toolholder seat needs to be modified according to insert profile to ensure clearance.

• For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Cutting depth maximum

For inserts, see pages: GIFI (352) • GIFI-E (349) • GIFI-E (full radius) (350) • GIMIY (349) • GINI-E (350) • GIPI (351)

• GIPI (full radius W<M) (351) • GIPI (full radius) (352) • GIPI-E (349) • GIPI-RX/LX (352) • TIPI-MT (648) • TIPI-WT (642)

GHIUR/L CDX

Undercutting and WF DCONMS

Turning Boring Bars DMIN CWX

KAPR LH HF

OAL

Right-hand shown

Designation CWX (1) DCONMS DMIN CDX (2) OAL LH WF HF KAPR (3)

GHIUR/L 20U 4.80 20.00 20.00 2.50 160.00 40.0 12.50 9.0 45.0 SR 76-1021 T-20/5

GHIUR/L 20-20-5 4.80 20.00 20.00 3.00 200.00 51.0 13.00 9.0 60.0 SR 76-1021 T-20/5

GHIUR/L 25U 6.40 25.00 25.00 3.00 160.00 50.0 15.50 11.5 45.0 SR 76-1022 T-20/5

GHIUR/L 25-25-6 6.40 25.00 25.00 3.50 200.00 60.0 16.00 11.5 60.0 SR 76-1022 T-20/5

(1) Maximum cutting width

(2) Cutting depth maximum

(3) Tool cutting edge angle

For inserts, see pages: GIPI-UR/UL (353)

f1 OAL HF

GHAIR/L-GI

Bars with Coolant Holes LH

for Internal Grooving and DMIN

Turning Adapters DMIN WF DCONMS

CDX LF (assembly)

Right-hand shown • LF(assembly)=OAL(holder)-f1+LF(adapter) • For LF(adapter) dimension, see GAIR/L adapters.

Designation DCONMS LH OAL WF HF f1 Adapter

GHAIR/L 25-32 25.00 25.0 200.00 19.70 11.5 3.0 GAIR/L 32.. SR 16-236 P T-15/5 PL 25

GHAIR/L 32-32 32.00 32.0 200.00 23.20 14.5 3.0 GAIR/L 32.. SR 16-236 P T-15/5 PL 32

GHAIR/L 32-40 32.00 40.0 200.00 24.00 14.5 3.0 GAIR/L 40.. SR 16-212 T-20/5 PL 32 SR 14-519

• For DMIN & CDX refer to GAIR/L adapters

For tools, see pages: GAIR/L (346)

345