Page 464 - DC_SWISS(Catalogue_TM_ES-EN)

P. 464

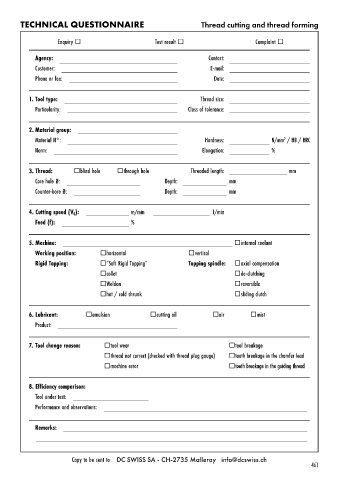

TECHNICAL QUESTIONNAIRE Thread cutting and thread forming

Enquiry Test result Complaint

Agency: Contact:

Customer: E-mail:

Phone or fax: Date:

1. Tool type: Thread size:

Particularity: Class of tolerance:

2. Material group:

Material N°: Hardness: N/mm / HB / HRC

2

Norm: Elongation: %

3. Thread: blind hole through hole Threaded length: mm

Core hole Ø: Depth: mm

Counter-bore Ø: Depth: mm

4. Cutting speed (V ): m/min 1/min

c

Feed (f): %

5. Machine: internal coolant

Working position: horizontal vertical

Rigid Tapping: “Soft Rigid Tapping“ Tapping spindle: axial compensation

collet de-clutching

Weldon reversible

hot / cold shrunk sliding clutch

6. Lubricant: emulsion cutting oil air mist

Product:

7. Tool change reason: tool wear tool breakage

thread not correct (checked with thread plug gauge) tooth breakage in the chamfer lead

machine error tooth breakage in the guiding thread

8. Efficiency comparison:

Tool under test:

Performance and observations:

Remarks:

Copy to be sent to DC SWISS SA - CH-2735 Malleray info@dcswiss.ch

461