Page 184 - Carbide drills I Thread cutting tools 2023

P. 184

v fc v fc v fc v fc v fc v f

v c

n

f z

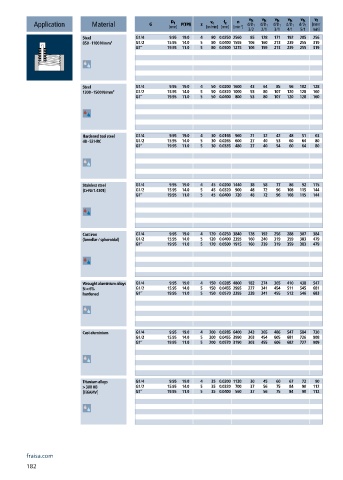

Application Material G [mm] P(TPI) z [m/min] [mm] [min ] -1 d/D 1 d/D 1 d/D 1 d/D 1 d/D 1 [mm/

D 1

3/2 2/1 3/1 4/1 5/1 min]

Steel G1/4 9.95 19.0 4 80 0.0250 2560 85 128 171 192 205 256

850 - 1100 N/mm² G1/2 15.95 14.0 5 80 0.0400 1595 106 160 213 239 255 319

G1‘‘ 19.95 11.0 5 80 0.0500 1275 106 159 213 239 255 319

Steel G1/4 9.95 19.0 4 50 0.0200 1600 43 64 85 96 102 128

1300 - 1500 N/mm² G1/2 15.95 14.0 5 50 0.0320 1000 53 80 107 120 128 160

G1‘‘ 19.95 11.0 5 50 0.0400 800 53 80 107 120 128 160

Hardened tool steel G1/4 9.95 19.0 4 30 0.0165 960 21 32 42 48 51 63

48 - 52 HRC G1/2 15.95 14.0 5 30 0.0265 600 27 40 53 60 64 80

G1‘‘ 19.95 11.0 5 30 0.0335 480 27 40 54 60 64 80

Stainless steel G1/4 9.95 19.0 4 45 0.0200 1440 38 58 77 86 92 115

[Cr-Ni/1.4301] G1/2 15.95 14.0 5 45 0.0320 900 48 72 96 108 115 144

G1‘‘ 19.95 11.0 5 45 0.0400 720 48 72 96 108 115 144

Cast iron G1/4 9.95 19.0 4 120 0.0250 3840 128 192 256 288 307 384

(lamellar / spheroidal) G1/2 15.95 14.0 5 120 0.0400 2395 160 240 319 359 383 479

G1‘‘ 19.95 11.0 5 120 0.0500 1915 160 239 319 359 383 479

Wrought aluminium alloys G1/4 9.95 19.0 4 150 0.0285 4800 182 274 365 410 438 547

Si < 6% G1/2 15.95 14.0 5 150 0.0455 2995 227 341 454 511 545 681

hardened G1‘‘ 19.95 11.0 5 150 0.0570 2395 228 341 455 512 546 683

Cast aluminium G1/4 9.95 19.0 4 200 0.0285 6400 243 365 486 547 584 730

G1/2 15.95 14.0 5 200 0.0455 3990 303 454 605 681 726 908

G1‘‘ 19.95 11.0 5 200 0.0570 3190 303 455 606 682 727 909

Titanium alloys G1/4 9.95 19.0 4 35 0.0200 1120 30 45 60 67 72 90

> 300 HB G1/2 15.95 14.0 5 35 0.0320 700 37 56 75 84 90 112

[Ti6Al4V] G1‘‘ 19.95 11.0 5 35 0.0400 560 37 56 75 84 90 112

fraisa.com

182