Page 109 - GARR_TOOL(CATALOG_INT)

P. 109

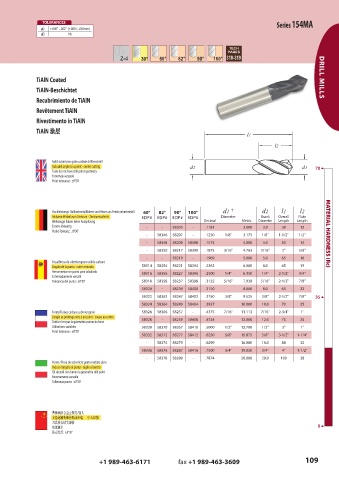

TOLERANCES Series 154MA

d1 +.000" –.002" (+.000 /–.050mm)

d2 h6

60° 82° 100° 318-319

TiAlN Coated DRILL MILLS

TiAlN-Beschichtet

Recubrimiento de TiAlN

Revêtement TiAlN

Rivestimento in TiAlN

TiAlN 涂层

涂层

Solid submicron grain carbide drill/end mill

Included angle to a point - center cutting 70 6

Tools do not have drill point geometry

Extremely versatile

Point tolerance: ±0°30'

Hochleistungs- VollhartmetallBohrer und fräser aus Feinkornhartmetall 60° 82° 90° 100° d1 † d2 l1 l2

Inklusive Winkel zum Zentrum - Zentrumsschnitt EDP# EDP# EDP# EDP# Diameter Shank Overall Flute

Werkzeuge haben keine Ausspitzung Decimal Metric Diameter Length Length

Extrem Vielseitig - - 58205 - .1181 3.000 3.0 38 12

Punkt-Toleranz: ±0°30'

- 58346 58207 - .1250 1/8" 3.175 1/8" 1-1/2" 1/2" MATERIAL HARDNESS (Rc)

- 58348 58209 58388 .1575 4.000 4.0 50 14

- 58350 58217 58390 .1875 3/16" 4.763 3/16" 2" 5/8"

- - 58219 - .1969 5.000 5.0 65 16

Fresa/Broca de submicrograno sólido carburo

Ángulo de la punta - corte centrado 58314 58354 58221 58394 .2362 6.000 6.0 65 19

Herramientas sin punta para taladrado 58316 58356 58227 58396 .2500 1/4" 6.350 1/4" 2-1/2" 3/4"

Extremadamente versátil

Tolerancia del punta: ±0°30' 58318 58358 58237 58398 .3125 5/16" 7.938 5/16" 2-1/2" 7/8"

58320 - 58239 58400 .3150 8.000 8.0 65 22

58322 58362 58247 58402 .3750 3/8" 9.525 3/8" 2-1/2" 7/8" 35 6

58324 58364 58249 58404 .3937 10.000 10.0 70 25

Forets/Fraises carbure submicrograin 58326 58366 58257 - .4375 7/16" 11.113 7/16" 2-3/4" 1"

L’angle se prolonge vers à un point - coupe au centre

Outils n'ont pas la géométrie pointe du foret 58328 - 58259 58408 .4724 12.000 12.0 75 25

Utilisations variables 58330 58370 58267 58410 .5000 1/2" 12.700 1/2" 3" 1"

Point tolerance: ±0°30'

58332 58372 58277 58412 .6250 5/8" 15.875 5/8" 3-1/2" 1-1/4"

- 58374 58279 - .6299 16.000 16.0 88 32

58336 58376 58287 58416 .7500 3/4" 19.050 3/4" 4" 1-1/2"

- 58378 58289 - .7874 20.000 20.0 100 38

Punte / Fresa de sub-micro grano metallo duro

Incluso l’angolo al punto - taglio al centro

Gli utensili non hanno la geometria drill point

Estremamente varsatile

Tolleranza punto: ±0°30'

整体硬质合金立铣刀/钻头

夹角逐渐变细并形成尖端 - 中心切削

刀具没有钻尖部份

功能极多 0 6

钻点允差: ±0°30'

+1 989-463-6171 fax +1 989-463-3609 109