Page 112 - GARR_TOOL(CATALOG_INT)

P. 112

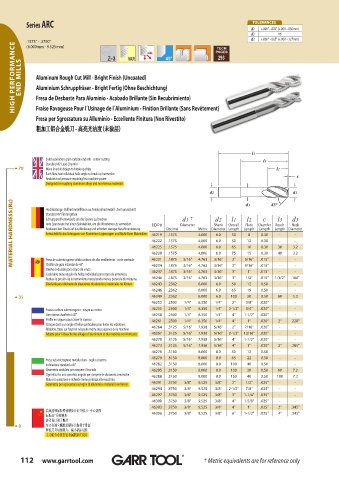

Series ARC TOLERANCES

d1 +.000" –.002" (+.000 –.050mm)

d2 h6

.1575" - .3750" 45° 293 d3 +.000" –.005" (+.000 –.127mm)

HIGH PERFORMANCE END MILLS Aluminum Rough Cut Mill - Bright Finish (Uncoated)

(4.000mm - 9.525mm)

Aluminium Schruppfräser - Bright Fertig (Ohne Beschichtung)

Fresa de Desbaste Para Aluminio - Acabado Brillante (Sin Recubrimiento)

Fraise Ravageuse Pour l´Usinage de l´Aluminium - Finition Brillante (Sans Revêtement)

Fresa per Sgrossatura su Alluminio - Eccellente Finitura (Non Rivestito)

粗加工铝合金铣刀 - 高亮光洁度(未涂层)

粗加工铝合金铣刀 高亮光洁度(未涂层)

Solid submicron grain carbide end mill - center cutting

Standard 45° Lead Chamfer

70 Wave knuckle design to break up chips

6

Each flute has individual helix angle to break up harmonics

Reduces tool pressure requiring less machine power

Designed for roughing aluminum alloys and non-ferrous materials

MATERIAL HARDNESS (Rc) MATERIAL HARDNESS (Rc) Hochleistungs- Vollhartmetallfräser aus Feinkornhartmetall - Zentrumsschnitt EDP# Decimal Diameter Metric Diameter Length Length Chamfer Length Diameter

Standard 45° Führungsfase

d1

c

†

d2

l1

d3

l2

l3

Schruppprofil entwickelt, um die Spänne zu brechen

Jede Spannnute hat einen Spiralwinkel, um die Vibrationen zu vermeiden

Reach

Neck

Overall

Shank

Flute

Length

Reduziert den Druck auf das Werkzeug und erfordert weniger Maschinenleistung

Entwickelt für das Schruppen von Aluminium Legierungen und Nicht-Eisen Materialien

-

4.000

8

46219

-

50

6.0

.1575

0.30

12

50

.1575

6.0

4.000

46222

-

0.30

-

4.000

30

3.2

0.30

.1575

46225

10

6.0

65

6.0

3.2

75

4.000

0.30

15

46228

40

.1575

Fresa de submicrograno sólido carburo de alto rendimiento - corte centrado

Chaflán de guía estándar de 45°

3/16"

4.763

.015"

9/16"

3/16"

.1875

46234

2"

Diseño ondulado para rotura de viruta

46237

1"

3"

.1875

4.763

3/16"

.015"

3/16"

Cada labio tiene ángulo de hélice individual para rotura de armónicos 46231 .1875 3/16" 4.763 3/16" 2" 5/16" .015" - - - - - -

Reduce la presión de la herramienta necesitando menos potencia de máquina 46240 .1875 3/16" 4.763 3/16" 3" 1/2" .015" 1-1/2" .160"

Diseñada para desbaste de aleaciones de aluminio y materiales no férricos 46243 .2362 6.000 6.0 50 12 0.50 - -

46246 .2362 6.000 6.0 65 19 0.50 - -

35 46249 .2362 6.000 6.0 100 20 0.50 60 5.2

6

46252 .2500 1/4" 6.350 1/4" 2" 3/8" .020" - -

Fraises carbure submicrograin - coupe au centre 46255 .2500 1/4" 6.350 1/4" 2-1/2" 3/4" .020" - -

Une norme chanfrein à 45° 46258 .2500 1/4" 6.350 1/4" 4" 1-1/2" .020" - -

Profile en vagues pour casser le copeau 46261 .2500 1/4" 6.350 1/4" 4" 1" .020" 2" .220"

Chaque dent a un angle d´hélice particulier pour éviter les vibrations

Réduit le stress sur l'outil et nécessite moins de puissance de la machine 46264 .3125 5/16" 7.938 5/16" 2" 7/16" .020" - -

Adapté pour l´ébauche des alliages d´aluminium et des matières non-ferreuses 46267 .3125 5/16" 7.938 5/16" 2-1/2" 13/16" .020" - -

46270 .3125 5/16" 7.938 5/16" 4" 1-1/2" .020" - -

46273 .3125 5/16" 7.938 5/16" 4" 1" .020" 2" .285"

46276 .3150 8.000 8.0 50 12 0.50 - -

46279 .3150 8.000 8.0 65 22 0.50 - -

Fresa sub-micrograno metallo duro - taglio al centro

Inclinazione standard a 45° 46282 .3150 8.000 8.0 100 40 0.50 - -

Geometria ondulata per rompere il truciolo 46285 .3150 8.000 8.0 100 20 0.50 60 7.2

Ogni elica ha uno specifico angolo per rompere le vibrazioni armoniche 46288 .3150 8.000 8.0 150 40 0.50 100 7.2

Riduce la pressione e richiede meno potenza alla macchina

Geometria per sgrossatura su leghe di alluminio e materiali non ferrosi 46291 .3750 3/8" 9.525 3/8" 2" 1/2" .025" - -

46294 .3750 3/8" 9.525 3/8" 2-1/2" 7/8" .025" - -

46297 .3750 3/8" 9.525 3/8" 3" 1-1/4" .025" - -

46300 .3750 3/8" 9.525 3/8" 4" 1-5/8" .025" - -

46303 .3750 3/8" 9.525 3/8" 4" 1" .025" 2" .345"

高效超细晶粒整体硬质合金立铣刀 - 中心切削

标准45° 导程倒角 46306 .3750 3/8" 9.525 3/8" 6" 1-1/2" .025" 4" .345"

波刃设计利于断屑

0 每刃有独立螺旋角破坏共振利于排屑

6

降低刀具切削阻力,减小机床功耗

专为铝合金及有色金属粗加工设计

112 www.garrtool.com ® ® ® † Metric equivalents are for reference only