Page 251 - GARR_TOOL(CATALOG_INT)

P. 251

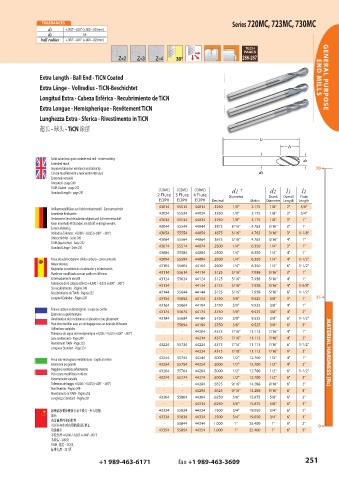

Series 720MC, 723MC, 730MC

TOLERANCES

d1 +.000" –.002" (+.000 –.050mm)

d2 h6

ball radius +.000" –.001" (+.000 –.025mm)

Z2 286-287

=

Extra Length - Ball End - TiCN Coated END MILLS GENERAL PURPOSE

Extra Länge - Vollradius - TiCN-Beschichtet

Longitud Extra - Cabeza Esférica - Recubrimiento de TiCN

Extra Longue - Hemispherique - Revêtement TiCN

Lunghezza Extra - Sferica - Rivestimento in TiCN

超长 球头 涂层

超长 - 球头 - TiCN 涂层

Solid submicron grain carbide end mill - center cutting

Extended reach

Improved abrasion resistance and lubricity 70 6

Can be modified with a neck within 48 hours

Extremely versatile

Uncoated - page 249

TiAlN Coated - page 252 (720MC) (723MC) (730MC) d1 †

Standard Length - page 231 d2 l1 l2

2 Flute 3 Flute 4 Flute Diameter Shank Overall Flute

EDP# EDP# EDP# Decimal Metric Diameter Length Length

43014 55514 44014 .1250 1/8" 3.175 1/8" 2" 5/8"

Vollhartmetallfräser aus Feinkornhartmetall - Zentrumsschnitt

Erweiterte Reichweite 43024 55524 44024 .1250 1/8" 3.175 1/8" 3" 3/4"

Verbesserte Verschleissbeständigkeit und Schmiereienschaft 43034 55534 44034 .1250 1/8" 3.175 1/8" 3" 1"

Kann innerhalb 48 Stunden am Schaft verjüngt werden

Extrem Vielseitig 43044 55544 44044 .1875 3/16" 4.763 3/16" 3" 1"

Vollradius Toleranz: +0,000 / –0,025 (+.000" –.001") 43054 55554 44054 .1875 3/16" 4.763 3/16" 3" 1-1/8"

Unbeschichtet - Seite 249 43064 55564 44064 .1875 3/16" 4.763 3/16" 4" 1"

TiAlN-Beschichtet - Seite 252

Standard Länge - Seite 231 43074 55574 44074 .2500 1/4" 6.350 1/4" 3" 1"

43084 55584 44084 .2500 1/4" 6.350 1/4" 4" 1"

Fresa de submicrograno sólido carburo - corte centrado 43094 55594 44094 .2500 1/4" 6.350 1/4" 4" 1-1/2"

Mayor alcance 43104 55604 44104 .2500 1/4" 6.350 1/4" 6" 1-1/2"

Mejoradas la resistencia a la abrasión y la lubricación

Puede ser modificado con un cuello en 48 horas 43114 55614 44114 .3125 5/16" 7.938 5/16" 3" 1"

Extremadamente versátil 43124 55624 44124 .3125 5/16" 7.938 5/16" 4" 1"

Tolerancia de la cabeza esférica +0,000 / –0,025 (+.000" –.001") 43134 - 44134 .3125 5/16" 7.938 5/16" 4" 1-5/8"

Sin recubrimiento - Página 249

Recubrimiento de TiAlN - Página 252 43144 55644 44144 .3125 5/16" 7.938 5/16" 6" 1-1/2"

Longitud Estándar - Página 231 43154 55654 44154 .3750 3/8" 9.525 3/8" 3" 1" 35 6

43164 55664 44164 .3750 3/8" 9.525 3/8" 4" 1"

Fraises carbure submicrograin - coupe au centre 43174 55674 44174 .3750 3/8" 9.525 3/8" 4" 2"

Extension supplémentaire

Amelioration de la resistance a l’abrasion et au glissement 43184 55684 44184 .3750 3/8" 9.525 3/8" 6" 1-1/2"

Peut etre modifier avec un col degage sous un delai de 48 heures - 55694 44194 .3750 3/8" 9.525 3/8" 6" 3"

Utilisations variables

Tolerance du rayon de hemispherique +0,000 / –0,025 (+.000" –.001") - - 44204 .4375 7/16" 11.113 7/16" 4" 1"

Sans revêtement - Page 249 - - 44214 .4375 7/16" 11.113 7/16" 4" 2"

Revêtement TiAlN - Page 252 43224 55724 44224 .4375 7/16" 11.113 7/16" 6" 1-1/2"

Longueur Standart - Page 231

- - 44234 .4375 7/16" 11.113 7/16" 6" 3" MATERIAL HARDNESS (Rc)

Fresa sub-micrograno metallo duro - taglio al centro 43244 55744 44244 .5000 1/2" 12.700 1/2" 4" 1"

Estensione più grande 43254 55754 44254 .5000 1/2" 12.700 1/2" 4" 2"

Maggiore resistenza all’abrasione 43264 55764 44264 .5000 1/2" 12.700 1/2" 6" 1-1/2"

Può essere modificata in 48 ore

Estremamente varsatile 43274 55774 44274 .5000 1/2" 12.700 1/2" 6" 3"

Tolleranza del raggio +0,000 / –0,025 (+.000" –.001") - - 44284 .5625 9/16" 14.288 9/16" 6" 2"

Non Rivestito - Pagina 249 - - 44294 .5625 9/16" 14.288 9/16" 6" 3"

Rivestimento in TiAlN - Pagina 252

Lunghezza Standard - Pagina 231 43304 55804 44304 .6250 5/8" 15.875 5/8" 6" 2"

- - 44314 .6250 5/8" 15.875 5/8" 6" 3"

超细晶粒整体硬质合金立铣刀 - 中心切削 43324 55824 44324 .7500 3/4" 19.050 3/4" 6" 2"

加长 43334 55834 44334 .7500 3/4" 19.050 3/4" 6" 3"

改善耐磨性和润滑性

可以在48小时内用轴颈进行修正 - 55844 44344 1.000 1" 25.400 1" 6" 2" 0 6

功能极多 43354 55854 44354 1.000 1" 25.400 1" 6" 3"

半径允差 +0,000 /–0,025 (+.000"–.001")

未涂层 - 249页

TiAlN 涂层 - 252页

标准长度

标准长度 - 231页

+1 989-463-6171 fax +1 989-463-3609 251