Page 315 - GARR_TOOL(CATALOG_INT)

P. 315

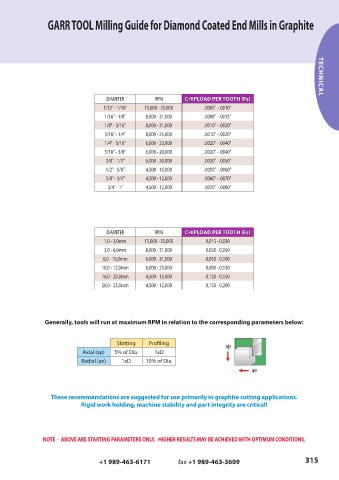

GARR TOOL Milling Guide for Diamond Coated End Mills in Graphite

CHIPLOAD PER TOOTH (Fz)

DIAMETER RPM CHIPL O AD PER T OO TH (Fz) TECHNICAL

1/32" - 1/16" 15,000 - 35,000 .0005" - .0010"

1/16" - 1/8" 8,000 - 31,000 .0008" - .0015"

1/8" - 3/16" 8,000 - 31,000 .0010" - .0020"

3/16" - 1/4" 8,000 - 25,000 .0010" - .0020"

1/4" - 5/16" 6,000 - 23,000 .0020" - .0040"

5/16" - 3/8" 6,000 - 20,000 .0020" - .0040"

3/8" - 1/2" 6,000 - 20,000 .0030" - .0050"

1/2" - 5/8" 4,500 - 15,000 .0050" - .0060"

5/8" - 3/4" 4,500 - 12,000 .0060" - .0070"

3/4" - 1" 4,500 - 12,000 .0070" - .0080"

CHIPLOAD PER TOOTH (Fz)

DIAMETER RPM CHIPL O AD PER T OO TH (Fz)

1,0 - 3,0mm 15,000 - 35,000 0,015 - 0,030

3,0 - 6,0mm 8,000 - 31,000 0,030 - 0,050

6,0 - 10,0mm 6,000 - 31,000 0,050 - 0,100

10,0 - 12,0mm 6,000 - 25,000 0,080 - 0,130

16,0 - 20,0mm 4,500 - 15,000 0,130 - 0,150

20,0 - 25,0mm 4,500 - 12,000 0,150 - 0,200

Generally, tools will run at maximum RPM in relation to the corresponding parameters below:

Slotting Profiling ap

Axial (ap) 5% of Dia. 1xD

Radial (ae) 1xD 10% of Dia.

ae

These recommendations are suggested for use primarily in graphite cutting applications.

Rigid work holding, machine stability and part integrity are critical!

NOTE - ABOVE ARE STARTING PARAMETERS ONLY. HIGHER RESULTS MAY BE ACHIEVED WITH OPTIMUM CONDITIONS.

+1 989-463-6171 fax +1 989-463-3609 315