Page 314 - GARR_TOOL(CATALOG_INT)

P. 314

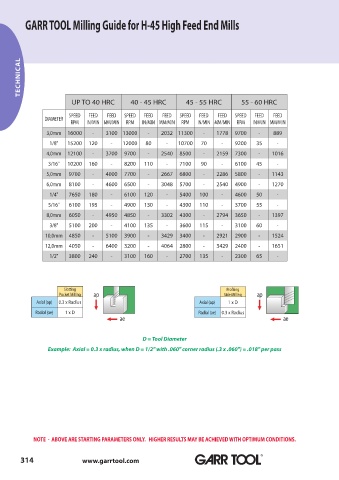

GARR TOOL Milling Guide for H-45 High Feed End Mills

TECHNICAL

UP TO 40 HRC 40 - 45 HRC 45 - 55 HRC 55 - 60 HRC

SPEED FEED FEED SPEED FEED FEED SPEED FEED FEED SPEED FEED FEED

DIAMETER

RPM IN/MIN MM/MIN RPM IN/MIN MM/MIN RPM IN/MIN MM/MIN RPM IN/MIN MM/MIN

3,0mm 16000 - 3100 13000 - 2032 11300 - 1778 9700 - 889

1/8" 15200 120 - 12000 80 - 10700 70 - 9200 35 -

4,0mm 12100 - 3700 9700 - 2540 8500 - 2159 7300 - 1016

3/16" 10200 160 - 8200 110 - 7100 90 - 6100 45 -

5,0mm 9700 - 4000 7700 - 2667 6800 - 2286 5800 - 1143

6,0mm 8100 - 4600 6500 - 3048 5700 - 2540 4900 - 1270

1/4" 7650 180 - 6100 120 - 5400 100 - 4600 50 -

5/16" 6100 195 - 4900 130 - 4300 110 - 3700 55 -

8,0mm 6050 - 4950 4850 - 3302 4300 - 2794 3650 - 1397

3/8" 5100 200 - 4100 135 - 3600 115 - 3100 60 -

10,0mm 4850 - 5100 3900 - 3429 3400 - 2921 2900 - 1524

12,0mm 4050 - 6400 3200 - 4064 2800 - 3429 2400 - 1651

1/2" 3800 240 - 3100 160 - 2700 135 - 2300 65 -

Slotting Profiling

Pocket Milling ap Side Milling ap

Axial (ap) 0.3 x Radius Axial (ap) 1 x D

Radial (ae) 1 x D Radial (ae) 0.3 x Radius

ae ae

D = Tool Diameter

Example: Axial = 0.3 x radius, when D = 1/2" with .060" corner radius (.3 x .060") = .018" per pass

NOTE - ABOVE ARE STARTING PARAMETERS ONLY. HIGHER RESULTS MAY BE ACHIEVED WITH OPTIMUM CONDITIONS.

314 www.garrtool.com ®