Page 313 - GARR_TOOL(CATALOG_INT)

P. 313

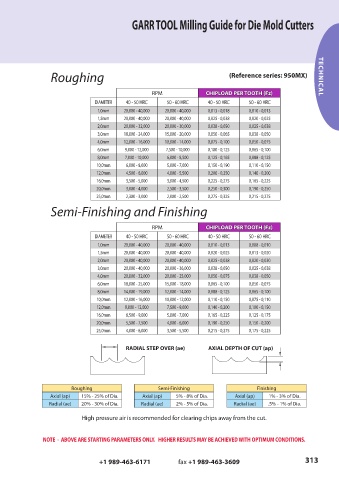

GARR TOOL Milling Guide for Die Mold Cutters

Roughing (Reference series: 950MX) TECHNICAL

RPM CHIPL O AD PER T OO TH (Fz)

CHIPLOAD PER TOOTH (Fz)

DIAMETER 40 - 50 HRC 50 - 60 HRC 40 - 50 HRC 50 - 60 HRC

1,0mm 20,000 - 40,000 20,000 - 40,000 0,013 - 0,018 0,010 - 0,013

1,5mm 20,000 - 40,000 20,000 - 40,000 0,025 - 0,038 0,020 - 0,025

2,0mm 20,000 - 32,000 20,000 - 30,000 0,038 - 0,050 0,025 - 0,038

3,0mm 18,000 - 24,000 15,000 - 20,000 0,050 - 0,065 0,038 - 0,050

4,0mm 12,000 - 16,000 10,000 - 14,000 0,075 - 0,100 0,050 - 0,075

6,0mm 9,000 - 12,000 7,500 - 10,000 0,100 - 0,125 0,065 - 0,100

8,0mm 7,000 - 10,000 6,000 - 8,500 0,125 - 0,165 0,088 - 0,125

10,0mm 6,000 - 8,000 5,000 - 7,000 0,150 - 0,190 0,110 - 0,150

12,0mm 4,500 - 6,000 4,000 - 5,500 0,200 - 0,250 0,140 - 0,200

16,0mm 3,500 - 5,000 3,000 - 4,500 0,225 - 0,275 0,165 - 0,225

20,0mm 3,000 - 4,000 2,500 - 3,500 0,250 - 0,300 0,190 - 0,250

25,0mm 2,300 - 3,000 2,000 - 2,500 0,275 - 0,325 0,215 - 0,275

Semi-Finishing and Finishing

CHIPLOAD PER TOOTH (Fz)

RPM CHIPL O AD PER T OO TH (Fz)

DIAMETER 40 - 50 HRC 50 - 60 HRC 40 - 50 HRC 50 - 60 HRC

1,0mm 20,000 - 40,000 20,000 - 40,000 0,010 - 0,013 0,008 - 0,010

1,5mm 20,000 - 40,000 20,000 - 40,000 0,020 - 0,025 0,013 - 0,020

2,0mm 20,000 - 40,000 20,000 - 40,000 0,025 - 0,038 0,020 - 0,030

3,0mm 20,000 - 40,000 20,000 - 36,000 0,038 - 0,050 0,025 - 0,038

4,0mm 20,000 - 32,000 20,000 - 25,000 0,050 - 0,075 0,038 - 0,050

6,0mm 18,000 - 25,000 15,000 - 18,000 0,065 - 0,100 0,050 - 0,075

8,0mm 14,000 - 19,000 12,000 - 14,000 0,088 - 0,125 0,065 - 0,100

10,0mm 12,000 - 16,000 10,000 - 12,000 0,110 - 0,150 0,075 - 0,110

12,0mm 9,000 - 12,000 7,500 - 9,000 0,140 - 0,200 0,100 - 0,150

16,0mm 6,500 - 9,000 5,000 - 7,000 0,165 - 0,225 0,125 - 0,175

20,0mm 5,500 - 7,500 4,000 - 6,000 0,190 - 0,250 0,150 - 0,200

25,0mm 4,000 - 6,000 3,500 - 5,500 0,215 - 0,275 0,175 - 0,225

RADIAL STEP OVER (ae) AXIAL DEPTH OF CUT (ap)

Roughing Semi-Finishing Finishing

Axial (ap) 15% - 25% of Dia. Axial (ap) 5% - 8% of Dia. Axial (ap) 1% - 3% of Dia.

Radial (ae) 20% - 30% of Dia. Radial (ae) 2% - 5% of Dia. Radial (ae) .5% - 1% of Dia.

High pressure air is recommended for clearing chips away from the cut.

NOTE - ABOVE ARE STARTING PARAMETERS ONLY. HIGHER RESULTS MAY BE ACHIEVED WITH OPTIMUM CONDITIONS.

+1 989-463-6171 fax +1 989-463-3609 313