Page 310 - GARR_TOOL(CATALOG_INT)

P. 310

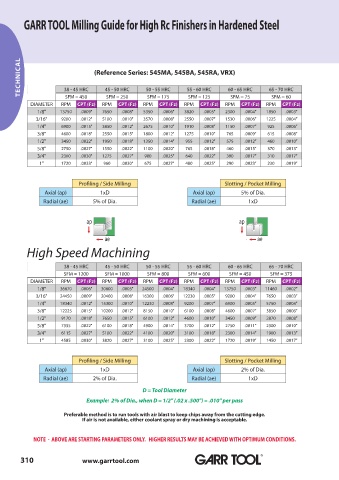

GARR TOOL Milling Guide for High Rc Finishers in Hardened Steel

TECHNICAL 38 - 45 HRC (Reference Series: 545MA, 545BA, 545RA, VRX) 65 - 70 HRC

60 - 65 HRC

50 - 55 HRC

45 - 50 HRC

55 - 60 HRC

SFM = 125

SFM = 175

SFM = 450

SFM = 60

SFM = 250

SFM = 75

CPT (Fz)

CPT (Fz)

CPT (Fz)

CPT (Fz)

DIAMETER RPM CPT (Fz) RPM CPT (Fz) RPM CPT (Fz) RPM CPT (Fz) RPM CPT (Fz) RPM CPT (Fz)

CPT (Fz)

CPT (Fz)

1/8" 13750 .0009" 7650 .0008" 5350 .0006" 3820 .0005" 2300 .0004" 1850 .0003"

3/16" 9200 .0012" 5100 .0010" 3570 .0008" 2550 .0007" 1530 .0006" 1225 .0004"

1/4" 6900 .0015" 3850 .0012" 2675 .0010" 1910 .0008" 1150 .0007" 925 .0006"

3/8" 4600 .0018" 2550 .0015" 1800 .0012" 1275 .0010" 765 .0009" 615 .0008"

1/2" 3450 .0022" 1950 .0018" 1350 .0014" 955 .0012" 575 .0012" 460 .0010"

5/8" 2750 .0027" 1550 .0022" 1100 .0020" 765 .0018" 460 .0015" 370 .0013"

3/4" 2300 .0030" 1275 .0027" 900 .0025" 640 .0022" 390 .0017" 310 .0017"

1" 1720 .0033" 960 .0030" 675 .0027" 480 .0025" 290 .0023" 230 .0019"

Profiling / Side Milling Slotting / Pocket Milling

Axial (ap) 1xD Axial (ap) 5% of Dia.

Radial (ae) 5% of Dia. Radial (ae) 1xD

ap ap

ae ae

High Speed Machining

38 - 45 HRC 45 - 50 HRC 50 - 55 HRC 55 - 60 HRC 60 - 65 HRC 65 - 70 HRC

SFM = 1200 SFM = 1000 SFM = 800 SFM = 600 SFM = 450 SFM = 375

CPT (Fz)

CPT (Fz)

CPT (Fz)

CPT (Fz)

CPT (Fz)

CPT (Fz)

DIAMETER RPM CPT (Fz) RPM CPT (Fz) RPM CPT (Fz) RPM CPT (Fz) RPM CPT (Fz) RPM CPT (Fz)

1/8" 36670 .0006" 30600 .0005" 24500 .0004" 18340 .0004" 13750 .0003" 11460 .0002"

3/16" 24450 .0009" 20400 .0008" 16300 .0006" 12230 .0005" 9200 .0004" 7650 .0003"

1/4" 18340 .0012" 15300 .0010" 12230 .0008" 9200 .0007" 6900 .0005" 5750 .0004"

3/8" 12225 .0015" 10200 .0012" 8150 .0010" 6100 .0008" 4600 .0007" 3850 .0006"

1/2" 9170 .0018" 7650 .0015" 6100 .0012" 4600 .0010" 3450 .0009" 2870 .0008"

5/8" 7335 .0022" 6100 .0018" 4900 .0014" 3700 .0012" 2750 .0011" 2300 .0010"

3/4" 6115 .0027" 5100 .0022" 4100 .0020" 3100 .0018" 2300 .0014" 1900 .0013"

1" 4585 .0030" 3820 .0027" 3100 .0025" 2300 .0022" 1720 .0019" 1450 .0017"

Profiling / Side Milling Slotting / Pocket Milling

Axial (ap) 1xD Axial (ap) 2% of Dia.

Radial (ae) 2% of Dia. Radial (ae) 1xD

D = Tool Diameter

Example: 2% of Dia., when D = 1/2" (.02 x .500") = .010" per pass

Preferable method is to run tools with air blast to keep chips away from the cutting edge.

If air is not available, either coolant spray or dry machining is acceptable.

NOTE - ABOVE ARE STARTING PARAMETERS ONLY. HIGHER RESULTS MAY BE ACHIEVED WITH OPTIMUM CONDITIONS.

310 www.garrtool.com ®