Page 105 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 105

USER GUIDE

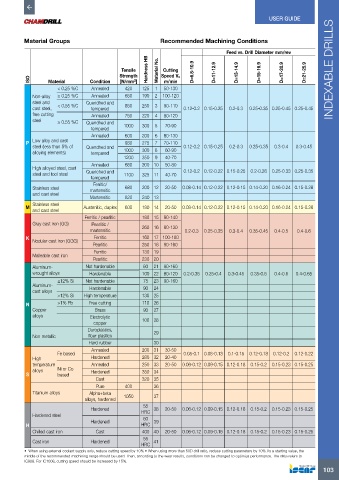

Material Groups Recommended Machining Conditions

Feed vs. Drill Diameter mm/rev

Tensile Hardness HB Material No. Cutting INDEXABLE DRILLS

Strength Speed Vc D=6.8-10.9 D=11-12.9 D=13-14.9 D=15-16.9 D=17-20.9 D=21-25.9

ISO Material Condition [N/mm ] m/min

2

< 0.25 %C Annealed 420 125 1 50-130

Non-alloy ≥ 0.25 %C Annealed 650 190 2 100-120

steel and Quenched and

cast steel, < 0.55 %C tempered 850 250 3 90-110 0.12-0.2 0.15-0.25 0.2-0.3 0.25-0.35 0.25-0.45 0.25-0.45

free cutting Annealed 750 220 4 90-120

steel ≥ 0.55 %C Quenched and

tempered 1000 300 5 70-90

Annealed 600 200 6 80-130

P Low alloy and cast 930 275 7 70-110

steel (less than 5% of Quenched and 0.12-0.2 0.15-0.25 0.2-0.3 0.25-0.35 0.3-0.4 0.3-0.45

alloying elements) tempered 1000 300 8 60-90

1200 350 9 40-70

Annealed 680 200 10 50-80

High alloyed steel, cast

steel and tool steel Quenched and 1100 325 11 40-70 0.12-0.2 0.12-0.22 0.15-0.25 0.2-0.28 0.25-0.33 0.25-0.35

tempered

Ferritic/

Stainless steel martensitic 680 200 12 20-50 0.08-0.14 0.12-0.22 0.12-0.15 0.14-0.20 0.16-0.24 0.15-0.28

and cast steel

Martensitic 820 240 13

Stainless steel

M Austenitic, duplex 600 180 14 20-50 0.08-0.14 0.12-0.22 0.12-0.15 0.14-0.20 0.16-0.24 0.15-0.28

and cast steel

Ferritic / pearlitic 180 15 90-140

Gray cast iron (GG) Pearlitic / 260 16 80-130

martensitic 0.2-0.3 0.25-0.35 0.3-0.4 0.35-0.45 0.4-0.5 0.4-0.6

K Nodular cast iron (GGG) Ferritic 160 17 100-180

Pearlitic 250 18 90-160

Ferritic 130 19

Malleable cast iron

Pearlitic 230 20

Aluminum- Not hardenable 60 21 90-160

wrought alloys Hardenable 100 22 80-120 0.2-0.35 0.25-0.4 0.3-0.45 0.35-0.5 0.4-0.6 0.4-0.65

≤12% Si Not hardenable 75 23 90-160

Aluminum- Hardenable 90 24

cast alloys

>12% Si High temperature 130 25

N >1% Pb Free cutting 110 26

Copper Brass 90 27

alloys Electrolytic

copper 100 28

Duroplastics, 29

Non metallic fiber plastics

Hard rubber 30

Annealed 200 31 30-50

Fe based 0.05-0.1 0.08-0.13 0.1-0.15 0.12-0.18 0.12-0.2 0.12-0.22

High Hardened 280 32 20-40

temperature Annealed 250 33 20-50 0.06-0.12 0.09-0.15 0.12-0.18 0.15-0.2 0.15-0.23 0.15-0.25

alloys Ni or Co Hardened 350 34

S based

Cast 320 35

Pure 400 36

Titanium alloys Alpha+beta

alloys, hardened 1050 37

55

Hardened HRC 38 20-50 0.06-0.12 0.09-0.15 0.12-0.18 0.15-0.2 0.15-0.23 0.15-0.25

Hardened steel

Hardened 60 39

H HRC

Chilled cast iron Cast 400 40 20-50 0.06-0.12 0.09-0.15 0.12-0.18 0.15-0.2 0.15-0.23 0.15-0.25

55

Cast iron Hardened 41

HRC

• When using external coolant supply only, reduce cutting speed by 10% • When using more than 5XD drill ratio, reduce cutting parameters by 10% As a starting value, the

middle of the recommended machining range should be used. Then, according to the wear results, conditions can be changed to optimize performance. The data refers to

IC908. For IC1008, cutting speed should be increased by 15%.

103