Page 306 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 306

USER GUIDE

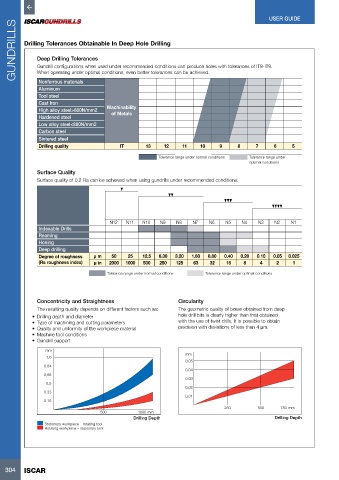

GUNDRILLS Drilling Tolerances Obtainable In Deep Hole Drilling

Deep Drilling Tolerances

Gundrill configurations when used under recommended conditions can produce holes with tolerances of IT8-IT9.

When operating under optimal conditions, even better tolerances can be achieved.

Nonferrous materials

Aluminum

Tool steel

Cast iron

High alloy steel>800N/mm2 Machinability

of Metals

Hardened steel

Low alloy steel<800N/mm2

Carbon steel

Sintered steel

Drilling quality IT 13 12 11 10 9 8 7 6 5

Tolerance range under normal conditions Tolerance range under

optimal conditions

Surface Quality

Surface quality of 0.2 Ra can be achieved when using gundrills under recommended conditions.

N12 N11 N10 N9 N8 N7 N6 N5 N4 N3 N2 N1

Indexable Drills

Reaming

Honing

Deep drilling

Degree of roughness μ m 50 25 12.5 6.30 3.20 1.60 0.80 0.40 0.20 0.10 0.05 0.025

(Ra roughness index) μ in 2000 1000 500 250 125 63 32 16 8 4 2 1

Tolerance range under normal conditions Tolerance range under optimal conditions

Concentricity and Straightness Circularity

The resulting quality depends on different factors such as: The geometric quality of bores obtained from deep

• Drilling depth and diameter hole drill bits is clearly higher than that obtained

• Type of machining and cutting parameters with the use of twist drills. It is possible to obtain

• Quality and uniformity of the workpiece material precision with deviations of less than 4 µm.

• Machine tool conditions

• Gundrill support

mm

mm

1.0

0.05

0.84

0.04

0,66

0.03

0.5

0.02

0.33

0.01

0.16

250 500 750 mm

500 1000 mm

Drilling Depth Drilling Depth

Stationary workpiece – rotating tool

Rotating workpiece – stationary tool

304 ISCAR