Page 523 - ISCAR(MILLINGCATALOG 38_2021)

P. 523

RE ...CS

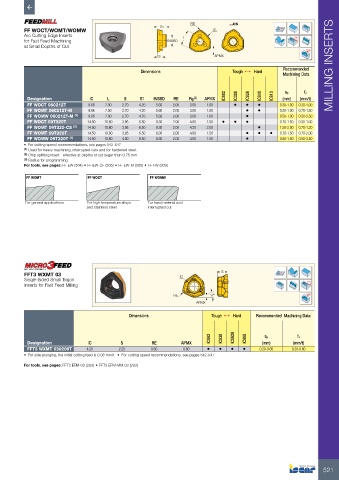

FF WOCT/WOMT/WOMW S1 IC

Arc Cutting Edge Inserts L Rd°

for Fast Feed Machining INSBD

at Small Depths of Cut

S APMX

Dimensions Tough 1 Hard Recommended MILLING INSERTS

Machining Data

IC882 IC328 IC928 IC908 IC910 ap fz

Designation IC L S S1 INSBD RE Rg (3) APMX (mm) (mm/t)

FF WOCT 060212T 9.86 7.00 2.70 4.20 5.60 2.00 3.00 1.00 • • • 0.30-1.00 0.30-1.00

FF WOMT 060212T-M 9.86 7.00 2.70 4.20 5.60 2.00 3.00 1.00 • • 0.30-1.00 0.70-1.50

FF WOMW 060212T-M (1) 9.86 7.00 2.70 4.70 5.60 2.00 3.00 1.00 • 0.50-1.00 0.50-3.50

FF WOCT 09T320T 14.50 10.60 3.95 6.50 9.30 2.00 4.00 1.50 • • • 0.70-1.50 0.30-1.00

FF WOMT 09T320-CS (2) 14.50 10.60 3.95 6.50 9.30 2.00 4.20 2.00 • 1.50-2.00 0.70-1.20

FF WOMT 09T320T 14.50 10.60 3.95 6.50 9.30 2.00 4.00 1.50 • • • 0.70-1.50 0.70-2.00

FF WOMW 09T320T (1) 14.50 10.60 4.00 6.50 9.30 2.00 4.00 1.50 • 0.80-1.50 0.50-3.50

• For cutting speed recommendations, see pages 542-547

(1) Used for heavy machining, interrupted cuts and for hardened steel.

(2) Chip splitting insert - effective at depths of cut larger than 0.75 mm.

(3) Radius for programming

For tools, see pages: FF EW (304) • FF EW-CF (305) • FF EW-M (305) • FF FW (309)

FF WOMT FF WOCT FF WOMW

For general applications For high temperature alloys For hard material and

and stainless steel interrupted cut

FFT3 WXMT 03 IC S

Single-Sided Small Trigon Rd°

Inserts for Fast Feed Milling

RE 17˚

APMX

Dimensions Tough 1 Hard Recommended Machining Data

IC882 IC830 IC5820 IC808 ap fz

Designation IC S RE APMX (mm) (mm/t)

FFT3 WXMT 030206T 4.20 2.20 0.60 0.60 • • • • 0.20-0.60 0.20-0.80

• For side plunging, the initial cutting feed is 0.08 mm/t • For cutting speed recommendations, see pages 542-547

For tools, see pages: FFT3 EFM-03 (293) • FFT3 EFM-MM 03 (293)

521