Page 601 - ISCAR(MILLINGCATALOG 38_2021)

P. 601

LSCWS A 0.003 A 50-52 HRc

M6 M6 ADJRGA

G2.5

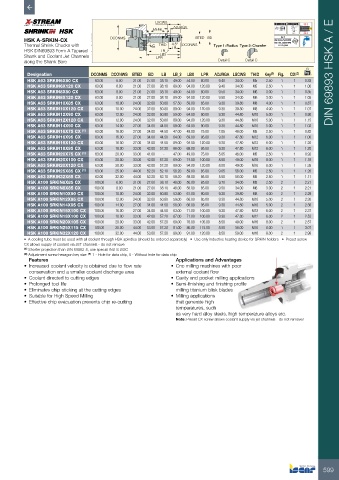

HSK A-SRKIN-CX DCONMS BTED BD HSK 50,63=25,000 RPM

Thermal Shrink Chucks with C THID 4.5° DCONWS Type 1: Radius Type 2: Chamfer HSK 100=20,000 RPM

U<1.0 gmm

LB

HSK DIN69893 Form A Tapered LB_2

LBX

Shank and Coolant Jet Channels LPR

along the Shank Bore Detail C Detail C

Designation DCONMS DCONWS BTED BD LB LB_2 LBX LPR ADJRGA LSCWS THID Key (2) Fig. CDI (3) kg DIN 69893 HSK A / E

HSK A63 SRKIN6X80 CX 63.00 6.00 21.00 27.00 38.10 49.00 54.00 80.00 9.40 34.00 M5 2.50 1 1 0.83

HSK A63 SRKIN6X120 CX 63.00 6.00 21.00 27.00 38.10 89.00 94.00 120.00 9.40 34.00 M5 2.50 1 1 1.00

HSK A63 SRKIN8X80 CX 63.00 8.00 21.00 27.00 38.10 49.00 54.00 80.00 9.50 34.00 M6 3.00 1 1 0.85

HSK A63 SRKIN8X120 CX 63.00 8.00 21.00 27.00 38.10 89.00 94.00 120.00 9.50 34.00 M6 3.00 1 1 1.05

HSK A63 SRKIN10X85 CX 63.00 10.00 24.00 32.00 50.80 57.50 59.00 85.00 9.30 39.80 M8 4.00 1 1 0.87

HSK A63 SRKIN10X120 CX 63.00 10.00 24.00 32.00 50.80 89.00 94.00 120.00 9.30 39.80 M8 4.00 1 1 1.07

HSK A63 SRKIN12X90 CX 63.00 12.00 24.00 32.00 50.80 59.00 64.00 90.00 9.30 44.80 M10 5.00 1 1 0.90

HSK A63 SRKIN12X120 CX 63.00 12.00 24.00 32.00 50.80 89.00 94.00 120.00 9.30 44.80 M10 5.00 1 1 1.15

HSK A63 SRKIN14X90 CX 63.00 14.00 27.00 34.00 44.50 59.00 64.00 90.00 9.30 44.80 M10 5.00 1 1 1.02

HSK A63 SRKIN16X75 CX (1) 63.00 16.00 27.00 34.00 44.50 47.00 49.00 75.00 7.05 46.00 M5 2.50 1 1 0.82

HSK A63 SRKIN16X95 CX 63.00 16.00 27.00 34.00 44.50 64.00 69.00 95.00 9.30 47.80 M12 6.00 1 1 1.00

HSK A63 SRKIN16X120 CX 63.00 16.00 27.00 34.00 44.50 89.00 94.00 120.00 9.30 47.80 M12 6.00 1 1 1.20

HSK A63 SRKIN18X95 CX 63.00 18.00 33.00 42.00 57.20 66.00 69.00 95.00 9.30 47.80 M12 6.00 1 1 1.20

HSK A63 SRKIN20X75 CX (1) 63.00 20.00 33.00 41.00 - 47.00 49.00 75.00 5.05 46.00 M5 2.50 1 1 0.92

HSK A63 SRKIN20X100 CX 63.00 20.00 33.00 42.00 57.20 69.00 74.00 100.00 8.50 49.00 M16 8.00 1 1 1.18

HSK A63 SRKIN20X120 CX 63.00 20.00 33.00 42.00 57.20 89.00 94.00 120.00 8.50 49.00 M16 8.00 1 1 1.38

HSK A63 SRKIN25X85 CX (1) 63.00 25.00 44.00 52.20 52.10 58.20 59.00 85.00 9.05 56.00 M5 2.50 1 1 1.26

HSK A63 SRKIN32X85 CX 63.00 32.00 44.00 52.20 52.10 58.20 59.00 85.00 5.50 56.00 M5 2.50 1 1 1.11

HSK A100 SRKIN6X85 CX 100.00 6.00 21.00 27.00 38.10 48.00 56.00 85.00 9.70 34.00 M5 2.50 2 1 2.21

HSK A100 SRKIN8X85 CX 100.00 8.00 21.00 27.00 38.10 48.00 56.00 85.00 9.50 34.00 M6 3.00 2 1 2.21

HSK A100 SRKIN10X90 CX 100.00 10.00 24.00 32.00 50.80 53.90 61.00 90.00 9.30 39.80 M8 4.00 2 1 2.29

HSK A100 SRKIN12X95 CX 100.00 12.00 24.00 32.00 50.80 59.00 66.00 95.00 9.30 44.80 M10 5.00 2 1 2.30

HSK A100 SRKIN14X95 CX 100.00 14.00 27.00 34.00 44.50 58.00 66.00 95.00 9.30 44.80 M10 5.00 2 1 2.36

HSK A100 SRKIN16X100 CX 100.00 16.00 27.00 34.00 44.50 63.00 71.00 100.00 9.30 47.80 M12 6.00 2 1 2.37

HSK A100 SRKIN18X100 CX 100.00 18.00 33.00 42.00 57.20 67.00 71.00 100.00 9.30 47.80 M12 6.00 2 1 2.53

HSK A100 SRKIN20X105 CX 100.00 20.00 33.00 42.00 57.20 69.00 76.00 105.00 8.50 49.00 M16 8.00 2 1 2.57

HSK A100 SRKIN25X115 CX 100.00 25.00 44.00 53.00 57.20 81.00 86.00 115.00 8.50 56.00 M16 8.00 1 1 3.07

HSK A100 SRKIN32X120 CX 100.00 32.00 44.00 53.00 57.20 89.00 91.00 120.00 8.50 59.00 M16 8.00 2 1 2.98

• A cooling tube must be used with all coolant through HSK spindles (should be ordered separately) • Use only inductive heating device for SRKIN holders • Preset screw

CX allows supply of coolant via JET channels - do not remove

(1) Shorter projection than DIN 69882-8, use special IND S DISC

(2) Adjustment screw hexagon key size (1) 1 - Hole for data chip, 0 - Without hole for data chip

Features Applications and Advantages

• Increased coolant velocity is obtained due to flow rate • Cnc milling machines with poor

conservation and a smaller coolant discharge area external coolant flow

• Coolant directed to cutting edges • Cavity and pocket milling applications

• Prolonged tool life • Semi-finishing and finishing profile

• Eliminates chip sticking at the cutting edges milling titanium blisk blades

• Suitable for High Speed Milling • Milling applications

• Effective chip evacuation prevents chip re-cutting that generate high

temperatures, such

as very hard alloy steels, high temperature alloys etc.

Note: Preset CX screw allows coolant supply via jet channels - do not remove!

599