Page 287 - ISCAR(TURNING-CATALOG-42-2022)

P. 287

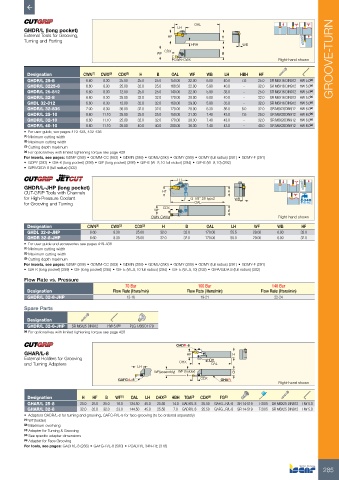

OAL

GHDR/L (long pocket) LH

External Tools for Grooving, HF H

Turning and Parting

HBH WB

WF CDX B

CWN-CWX Right-hand shown GROOVE-TURN

Designation CWN (1) CWX (2) CDX (3) H B OAL WF WB LH HBH HF

GHDR/L 25-8 6.60 8.30 25.00 25.0 25.0 150.00 22.00 6.00 40.0 7.6 25.0 SR M6X16 DIN912 HW 5.0 (a)

GHDR/L 3225-8 6.60 8.30 25.00 32.0 25.0 168.50 22.00 5.90 40.0 - 32.0 SR M6X16 DIN912 HW 5.0 (a)

GHDR/L 25-812 6.60 8.30 12.00 25.0 25.0 140.00 22.00 5.90 33.0 - 25.0 SR M6X16 DIN912 HW 5.0 (a)

GHDR/L 32-8 6.60 8.30 25.00 32.0 32.0 170.00 29.00 6.00 40.0 - 32.0 SR M6X16 DIN912 HW 5.0 (a)

GHDL 32-812 6.60 8.30 12.00 32.0 32.0 160.00 29.00 5.90 33.0 - 32.0 SR M6X16 DIN912 HW 5.0 (a)

GHDR/L 32-836 7.00 8.30 36.00 32.0 32.0 170.00 28.90 6.30 56.0 8.0 32.0 SR M8X20DIN912 HW 6.0 (a)

GHDR/L 25-10 8.60 11.10 25.00 25.0 25.0 150.00 21.30 7.40 43.0 7.6 25.0 SR M8X20DIN912 HW 6.0 (a)

GHDR/L 32-10 8.60 11.10 25.00 32.0 32.0 170.00 28.30 7.40 43.0 - 32.0 SR M8X20DIN912 HW 6.0 (a)

GHDR/L 40-10 8.60 11.10 25.00 40.0 40.0 200.00 36.30 7.40 43.0 - 40.0 SR M8X20DIN912 HW 6.0 (a)

• For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Cutting depth maximum

(a) For optional key with limited tightening torque see page 428

For inserts, see pages: GDMF (288) • GDMM-CC (583) • GDMN (289) • GDMU (290) • GDMY (289) • GDMY (full radius) (291) • GDMY-F (291)

• GDPY (293) • GIA-K (long pocket) (299) • GIF (long pocket) (298) • GIF-E (W=8,10 full radius) (294) • GIF-E (W=8,10) (292)

• GIPA/GIDA 8 (full radius) (302)

LH

GHDR/L-JHP (long pocket)

CUT-GRIP Tools with Channels HF H

for High-Pressure Coolant G 1/8"-28 typx2 WB

for Grooving and Turning OAL Bar Max

WF CDX B

CWN-CWX Right-hand shown

Designation CWN (1) CWX (2) CDX (3) H B OAL LH WF WB HF

GHDL 32-8-JHP 6.60 8.30 25.00 32.0 32.0 170.00 55.5 29.00 6.00 32.0

GHDR 32-8-JHP 6.60 8.30 25.00 32.0 32.0 170.00 55.0 29.00 6.00 32.0

• For user guide and accessories see pages 419-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Cutting depth maximum

For inserts, see pages: GDMF (288) • GDMM-CC (583) • GDMN (289) • GDMU (290) • GDMY (289) • GDMY (full radius) (291) • GDMY-F (291)

• GIA-K (long pocket) (299) • GIF (long pocket) (298) • GIF-E (W=8,10 full radius) (294) • GIF-E (W=8,10) (292) • GIPA/GIDA 8 (full radius) (302)

Flow Rate vs. Pressure

70 Bar 100 Bar 140 Bar

Designation Flow Rate (liters/min) Flow Rate (liters/min) Flow Rate (liters/min)

GHDR/L 32-8-JHP 13-16 19-21 22-24

Spare Parts

Designation

GHDR/L 32-8-JHP SR M6X25 DIN912 HW 5.0 (a) PLG 1/8ISO1179

(a) For optional key with limited tightening torque see page 428

GADR-8

GHAR/L-8 HF H

External Holders for Grooving HBH

and Turning Adapters OHX OAL

LH

WF(assembly) WF (holder) B

GAFG-L-8 CDX GHAR

Right-hand shown

Designation H HF B WF (1) OAL LH OHX (2) HBH TGA (3) CDX (4) FG (5)

GHAR/L 25-8 25.0 25.0 25.0 16.0 124.50 45.0 25.50 14.0 GADR/L 8 25.50 GAFG...R/L-8 SR 14-519 T-20/5 SR M6X25 DIN912 HW 5.0

GHAR/L 32-8 32.0 32.0 32.0 23.0 144.50 45.0 25.50 7.0 GADR/L 8 25.50 GAFG...R/L-8 SR 14-519 T-20/5 SR M6X25 DIN912 HW 5.0

• Adapters GADR/L-8 for turning and grooving, GAFG-R/L-8 for face-grooving (to be ordered separately)

(1) WF(holder)

(2) Maximum overhang

(3) Adapter for Turning & Grooving

(4) See specific adapter dimensions

(5) Adapter for Face Grooving

For tools, see pages: GADR/L-8 (286) • GAFG-R/L-8 (580) • PCADR/L 34N-RE (318)

285