Page 286 - ISCAR(TURNING-CATALOG-42-2022)

P. 286

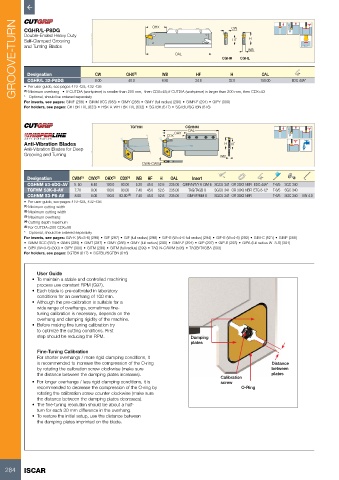

GROOVE-TURN CGHR/L-P8DG CW OHX (1) OHX 6.80 OAL 24.8 CGHR H CW CGHL WB 150.00 EDG 44A*

Double-Ended Heavy Duty

H

HF

Self-Clamped Grooving

and Turning Blades

Designation

WB

OAL

HF

CGHR/L 32-P8DG

40.0

8.00

32.0

• For user guide, see pages 419-428, 432-436

(1) Minimum overhang • If CUTDIA (workpiece) is smaller than 200 mm, then CDX=48; if CUTDIA (workpiece) is larger than 200 mm, then CDX=43

* Optional, should be ordered separately

For inserts, see pages: GIMF (288) • GIMM 8CC (583) • GIMY (288) • GIMY (full radius) (290) • GIMY-F (291) • GIPY (300)

For holders, see pages: C#-TBK-R/L (623) • HSK A-WH-TBK-R/L (632) • SGTBK (617) • SGTBU/SGTBN (616)

TGFHM CGHNM

CDX OHX OAL

Anti-Vibration Blades H HF

Anti-Vibration Blades for Deep

Grooving and Turning WB

CWN-CWX

Designation CWN (1) CWX (2) OHX (3) CDX (4) WB HF H OAL Insert

CGHNM 53-6DG-AV 5. 50 6.40 100.0 93.00 5.20 45.0 52.6 235.00 GIMF/N/T/Y 6 GIM 6 SGCU 341 OR 30X3 NBR EDG 44A* T-6/5 SGC 340

TGFHM 53K-8-AV 7.70 9.00 100.0 93.00 7.40 45.0 52.6 235.00 TAG/TAGB 8 SGCU 341 OR 30X3 NBR ETG 8-12* T-6/5 SGC 340

CGHNM 53-P8-AV 8.00 8.00 100.0 93.00 (5) 7.40 45.0 52.6 235.00 GIMY/F/MM 8 SGCU 341 OR 30X3 NBR T-6/5 SGC 340 HW 4.0

• For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Maximum overhang

(4) Cutting depth maximum

(5) For CUTDIA<200 CDX=98

* Optional, should be ordered separately

For inserts, see pages: GIA-K (W=3-6) (298) • GIF (297) • GIF (full radius) (298) • GIF-E (W=4-6 full radius) (294) • GIF-E (W=4-6) (292) • GIM-C (521) • GIMF (288)

• GIMM 8CC (583) • GIMN (289) • GIMT (287) • GIMY (288) • GIMY (full radius) (290) • GIMY-F (291) • GIP (297) • GIP-E (293) • GIPA (full radius W=3-6) (301)

• GIPA (W=3-6) (300) • GIPY (300) • GITM (299) • GITM (full radius) (299) • TAG N-C/W/M (506) • TAGB/TAGBA (333)

For holders, see pages: SGTBK (617) • SGTBU/SGTBN (616)

User Guide

• To maintain a stable and controlled machining

process use constant RPM (G97).

• Each blade is pre-calibrated in laboratory

conditions for an overhang of 100 mm.

• Although the pre-calibration is suitable for a

wide range of overhangs, sometimes fine-

tuning calibration is necessary, depends on the

overhang and clamping rigidity of the machine.

• Before making fine tuning calibration try

to optimize the cutting conditions. First

step should be reducing the RPM. Damping

plates

Fine-Tuning Calibration

For shorter overhangs / more rigid clamping conditions, it

is recommended to increase the compression of the O-ring Distance

by rotating the calibration screw clockwise (make sure between

the distance between the damping plates increases). plates

Calibration

• For longer overhangs / less rigid clamping conditions, it is screw

recommended to decrease the compression of the O-ring by O-Ring

rotating the calibration screw counter clockwise (make sure

the distance between the damping plates decreases).

• The fine-tuning resolution should be about a half-

turn for each 30 mm difference in the overhang.

• To restore the initial setup, use the distance between

the damping plates imprinted on the blade.

284 ISCAR