Page 116 - 21-036 APPLITEC catalogue.indb

P. 116

v f

d 1

v c

a p

f z

n

Q

a e

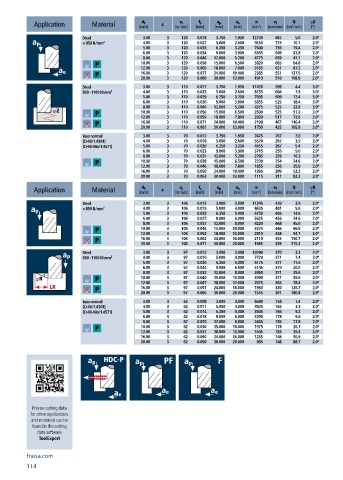

Application Material [mm] z [m/min] [mm] [mm] [mm] [min ] -1 [mm/min] [cm /min] jZ

3

[°]

Steel 3.00 3 120 0.018 3.750 1.950 12730 687 5.0 2.0°

< 850 N/mm² 4.00 3 120 0.027 5.000 2.600 9550 774 10.1 2.0°

5.00 3 120 0.033 6.250 3.250 7640 756 15.4 2.0°

6.00 3 120 0.034 9.000 3.900 6365 649 22.8 2.0°

8.00 3 120 0.046 12.000 5.200 4775 659 41.1 2.0°

10.00 3 120 0.058 15.000 6.500 3820 665 64.8 2.0°

12.00 3 120 0.065 18.000 7.800 3185 621 87.2 2.0°

16.00 3 120 0.077 24.000 10.400 2385 551 137.5 2.0°

20.00 3 120 0.089 30.000 13.000 1910 510 198.9 2.0°

Steel 3.00 3 110 0.017 3.750 1.950 11670 595 4.4 3.0°

850 - 1100 N/mm² 4.00 3 110 0.023 5.000 2.600 8755 604 7.9 3.0°

5.00 3 110 0.029 6.250 3.250 7005 609 12.4 3.0°

6.00 3 110 0.030 9.000 3.900 5835 525 18.4 3.0°

8.00 3 110 0.040 12.000 5.200 4375 525 32.8 3.0°

10.00 3 110 0.050 15.000 6.500 3500 525 51.2 3.0°

12.00 3 110 0.059 18.000 7.800 2920 517 72.6 3.0°

16.00 3 110 0.071 24.000 10.400 2190 467 116.4 3.0°

20.00 3 110 0.081 30.000 13.000 1750 425 165.9 3.0°

Inox normal 3.00 3 70 0.012 3.750 1.950 7425 267 2.0 2.0°

[Cr-Ni/1.4301] 4.00 3 70 0.016 5.000 2.600 5570 267 3.5 2.0°

[Cr-Ni-Mo/1.4571] 5.00 3 70 0.020 6.250 3.250 4455 267 5.4 2.0°

6.00 3 70 0.023 9.000 3.900 3715 256 9.0 2.0°

8.00 3 70 0.031 12.000 5.200 2785 259 16.2 2.0°

10.00 3 70 0.038 15.000 6.500 2230 254 24.8 2.0°

12.00 3 70 0.046 18.000 7.800 1855 256 35.9 2.0°

16.00 3 70 0.050 24.000 10.400 1395 209 52.2 2.0°

20.00 3 70 0.063 30.000 13.000 1115 211 82.2 2.0°

v c

f z

Q

d 1

v f

n

a p

a e

Application Material [mm] z [m/min] [mm] [mm] [mm] [min ] -1 [mm/min] [cm /min] jR

[°]

3

Steel 3.00 3 106 0.013 3.000 3.000 11245 439 3.9 2.0°

< 850 N/mm² 4.00 3 106 0.019 5.000 4.000 8435 481 9.6 2.0°

5.00 3 106 0.023 6.250 5.000 6750 466 14.6 2.0°

6.00 3 106 0.027 9.000 6.000 5625 456 24.6 2.0°

8.00 3 106 0.037 12.000 8.000 4220 468 45.0 2.0°

10.00 3 106 0.046 15.000 10.000 3375 466 69.9 2.0°

12.00 3 106 0.052 18.000 12.000 2810 438 94.7 2.0°

16.00 3 106 0.062 24.000 16.000 2110 393 150.7 2.0°

20.00 3 106 0.071 30.000 20.000 1685 359 215.3 2.0°

Steel 3.00 3 97 0.012 3.000 3.000 10290 370 3.3 2.0°

850 - 1100 N/mm² 4.00 3 97 0.016 5.000 4.000 7720 371 7.4 2.0°

5.00 3 97 0.020 6.250 5.000 6175 371 11.6 2.0°

6.00 3 97 0.024 9.000 6.000 5145 370 20.0 2.0°

8.00 3 97 0.032 12.000 8.000 3860 371 35.6 2.0°

10.00 3 97 0.040 15.000 10.000 3090 371 55.6 2.0°

12.00 3 97 0.047 18.000 12.000 2575 363 78.4 2.0°

16.00 3 97 0.057 24.000 16.000 1930 330 126.7 2.0°

20.00 3 97 0.065 30.000 20.000 1545 301 180.8 2.0°

Inox normal 3.00 3 62 0.008 3.000 3.000 6580 158 1.4 2.0°

[Cr-Ni/1.4301] 4.00 3 62 0.011 5.000 4.000 4935 163 3.3 2.0°

[Cr-Ni-Mo/1.4571] 5.00 3 62 0.014 6.250 5.000 3945 166 5.2 2.0°

6.00 3 62 0.018 9.000 6.000 3290 178 9.6 2.0°

8.00 3 62 0.025 12.000 8.000 2465 185 17.8 2.0°

10.00 3 62 0.030 15.000 10.000 1975 178 26.7 2.0°

12.00 3 62 0.037 18.000 12.000 1645 183 39.4 2.0°

16.00 3 62 0.040 24.000 16.000 1235 148 56.9 2.0°

20.00 3 62 0.050 30.000 20.000 985 148 88.7 2.0°

Precise cutting data

for other applications

and materials can be

found in the cutting

data software

ToolExpert

fraisa.com

114