Page 174 - Carbide drills I Thread cutting tools 2023

P. 174

f z

n

P

v c

v f

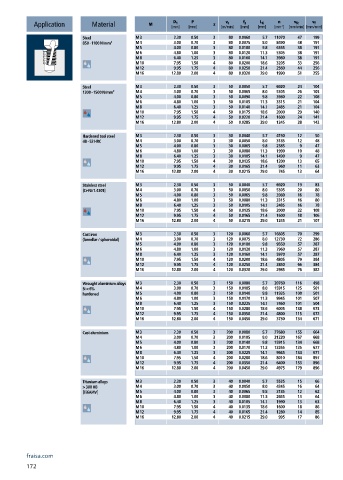

Application Material M [mm] [mm] z [m/min] [mm] [mm] [min ] [mm/min] [mm/min]

L K

D 1

v fc

-1

Steel M 3 2.30 0.50 3 80 0.0060 5.7 11070 47 199

850 - 1100 N/mm² M 4 3.00 0.70 3 80 0.0075 8.0 8490 48 191

M 5 4.00 0.80 3 80 0.0100 9.8 6365 38 191

M 6 4.80 1.00 3 80 0.0120 11.3 5305 38 191

M 8 6.40 1.25 3 80 0.0160 14.1 3980 38 191

M 10 7.95 1.50 4 80 0.0200 18.6 3205 53 256

M 12 9.95 1.75 4 80 0.0250 21.4 2560 44 256

M 16 12.80 2.00 4 80 0.0320 29.0 1990 51 255

Steel M 3 2.30 0.50 3 50 0.0050 5.7 6920 24 104

1300 - 1500 N/mm² M 4 3.00 0.70 3 50 0.0065 8.0 5305 26 103

M 5 4.00 0.80 3 50 0.0090 9.8 3980 22 108

M 6 4.80 1.00 3 50 0.0105 11.3 3315 21 104

M 8 6.40 1.25 3 50 0.0140 14.1 2485 21 104

M 10 7.95 1.50 4 50 0.0175 18.6 2000 29 140

M 12 9.95 1.75 4 50 0.0220 21.4 1600 24 141

M 16 12.80 2.00 4 50 0.0285 29.0 1245 28 142

Hardened tool steel M 3 2.30 0.50 3 30 0.0040 5.7 4150 12 50

48 - 52 HRC M 4 3.00 0.70 3 30 0.0050 8.0 3185 12 48

M 5 4.00 0.80 3 30 0.0065 9.8 2385 9 47

M 6 4.80 1.00 3 30 0.0080 11.3 1990 10 48

M 8 6.40 1.25 3 30 0.0105 14.1 1490 9 47

M 10 7.95 1.50 4 30 0.0135 18.6 1200 13 65

M 12 9.95 1.75 4 30 0.0165 21.4 960 11 63

M 16 12.80 2.00 4 30 0.0215 29.0 745 13 64

Stainless steel M 3 2.30 0.50 3 50 0.0040 5.7 6920 19 83

[Cr-Ni/1.4301] M 4 3.00 0.70 3 50 0.0050 8.0 5305 20 80

M 5 4.00 0.80 3 50 0.0065 9.8 3980 16 78

M 6 4.80 1.00 3 50 0.0080 11.3 3315 16 80

M 8 6.40 1.25 3 50 0.0105 14.1 2485 16 78

M 10 7.95 1.50 4 50 0.0135 18.6 2000 22 108

M 12 9.95 1.75 4 50 0.0165 21.4 1600 18 106

M 16 12.80 2.00 4 50 0.0215 29.0 1245 21 107

Cast iron M 3 2.30 0.50 3 120 0.0060 5.7 16605 70 299

(lamellar / spheroidal) M 4 3.00 0.70 3 120 0.0075 8.0 12730 72 286

M 5 4.00 0.80 3 120 0.0100 9.8 9550 57 287

M 6 4.80 1.00 3 120 0.0120 11.3 7960 57 287

M 8 6.40 1.25 3 120 0.0160 14.1 5970 57 287

M 10 7.95 1.50 4 120 0.0200 18.6 4805 79 384

M 12 9.95 1.75 4 120 0.0250 21.4 3840 66 384

M 16 12.80 2.00 4 120 0.0320 29.0 2985 76 382

Wrought aluminium alloys M 3 2.30 0.50 3 150 0.0080 5.7 20760 116 498

Si < 6% M 4 3.00 0.70 3 150 0.0105 8.0 15915 125 501

hardened M 5 4.00 0.80 3 150 0.0140 9.8 11935 100 501

M 6 4.80 1.00 3 150 0.0170 11.3 9945 101 507

M 8 6.40 1.25 3 150 0.0225 14.1 7460 101 504

M 10 7.95 1.50 4 150 0.0280 18.6 6005 138 673

M 12 9.95 1.75 4 150 0.0350 21.4 4800 115 672

M 16 12.80 2.00 4 150 0.0450 29.0 3730 134 671

Cast aluminium M 3 2.30 0.50 3 200 0.0080 5.7 27680 155 664

M 4 3.00 0.70 3 200 0.0105 8.0 21220 167 668

M 5 4.00 0.80 3 200 0.0140 9.8 15915 134 668

M 6 4.80 1.00 3 200 0.0170 11.3 13265 135 677

M 8 6.40 1.25 3 200 0.0225 14.1 9945 134 671

M 10 7.95 1.50 4 200 0.0280 18.6 8010 184 897

M 12 9.95 1.75 4 200 0.0350 21.4 6400 153 896

M 16 12.80 2.00 4 200 0.0450 29.0 4975 179 896

Titanium alloys M 3 2.30 0.50 3 40 0.0040 5.7 5535 15 66

> 300 HB M 4 3.00 0.70 3 40 0.0050 8.0 4245 16 64

[Ti6Al4V] M 5 4.00 0.80 3 40 0.0065 9.8 3185 12 62

M 6 4.80 1.00 3 40 0.0080 11.3 2655 13 64

M 8 6.40 1.25 3 40 0.0105 14.1 1990 13 63

M 10 7.95 1.50 4 40 0.0135 18.6 1600 18 86

M 12 9.95 1.75 4 40 0.0165 21.4 1280 14 85

M 16 12.80 2.00 4 40 0.0215 29.0 995 17 86

fraisa.com

172