Page 180 - GARR_TOOL(CATALOG_INT)

P. 180

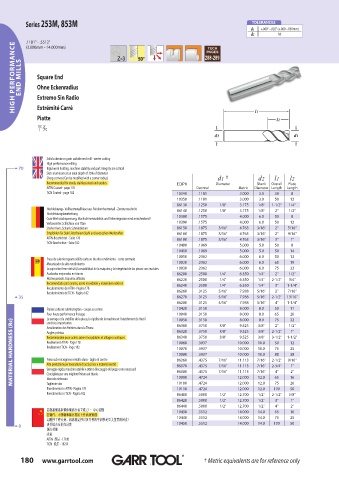

Series 253M, 853M TOLERANCES

d1 +.000" –.002" (+.000 –.050mm)

d2 h6

.1181" - .5512" 288-289

HIGH PERFORMANCE END MILLS Square End

(3.000mm - 14.000mm)

Ohne Eckenradius

Extremo Sin Radio

Extrémité Carré

Piatte

平头

平头

Solid submicron grain carbide end mill - center cutting

High performance milling

70 Rigid work holding, machine stability and part integrity are critical!

6

Slots aluminum at an axial depth of 25% of diameter

Sharp corners (Can be modified with a corner radius) d1 † d2 l1 l2

Recommended for steels, stainless steel and exotics EDP# Diameter Shank Overall Flute

AlTiN Coated - page 178 Decimal Metric Diameter Length Length

TiCN Coated - page 182 10340 .1181 3.000 3.0 38 8

10350 .1181 3.000 3.0 50 12

86130 .1250 1/8" 3.175 1/8" 1-1/2" 1/4"

Hochleistungs- Vollhartmetallfräser aus Feinkornhartmetall - Zentrumsschnitt 86140 .1250 1/8" 3.175 1/8" 2" 1/2"

Hochleistungsbearbeitung

Gute Werkstückspannung, Machschinenstabilität und Teileintegration sind entscheidend ! 10380 .1575 4.000 6.0 50 8

Verbessertes Schlichten von Titan 10390 .1575 4.000 6.0 50 12

Starker Kern, Scharfe Schneidecken 86150 .1875 3/16" 4.763 3/16" 2" 5/16"

Empfohlen für Stahl, Rostfreiem Stahl und exotischen Werkstoffen 86160 .1875 3/16" 4.763 3/16" 2" 9/16"

AlTiN-Beschichtet - Seite 178 86180 .1875 3/16" 4.763 3/16" 3" 1"

TiCN-Beschichtet - Seite 182

10400 .1969 5.000 5.0 50 8

10410 .1969 5.000 5.0 50 14

10010 .2362 6.000 6.0 50 12

Fresa de submicrograno sólido carburo de alto rendimiento - corte centrado

Mecanizado de alto rendimiento 10020 .2362 6.000 6.0 65 19

La sujección firme del útil, la estabilidad de la máquina y la integridad de las piezas son cruciales 10030 .2362 6.000 6.0 75 32

Acabados mejorados en titanio 86200 .2500 1/4" 6.350 1/4" 2" 1/2"

Núcleo pesado, Esquinas afiladas 86220 .2500 1/4" 6.350 1/4" 2-1/2" 3/4"

Recomendado para aceros, acero inoxidable y materiales exóticos 86240 .2500 1/4" 6.350 1/4" 3" 1-1/4"

Recubrimiento de AlTiN - Página 178

Recubrimiento de TiCN - Página 182 86260 .3125 5/16" 7.938 5/16" 2" 7/16"

35 86270 .3125 5/16" 7.938 5/16" 2-1/2" 13/16"

6

86280 .3125 5/16" 7.938 5/16" 4" 1-1/4"

Fraises carbure submicrograin - coupe au centre 10420 .3150 8.000 8.0 50 11

8.0

Pour haute performance fraisage 10040 .3150 3/8" 8.000 3/8" 2-1/2" 1/2"

65

20

Le serrage et la stabilite de la piece, la rigidite de la machine et l’atatchment de l’outil

.3150

10050

75

32

8.0

8.000

MATERIAL HARDNESS (Rc) Recommandee pour aciers, aciers inoxydables et alliages exotiques 86340 .3750 7/16" 10.000 7/16" 3-1/2" 1-1/2"

sont tres importantes

2"

.3750

9.525

86300

Amelioration des finitions dans le Titane

9.525

1"

86320

3/8"

.3750

3/8"

Angles pointus

9.525

3/8"

3/8"

Revêtement AlTiN - Page 178

12

.3937

50

10060

10.0

Revêtement TiCN - Page 182

.3937

10.000

10070

10.0

25

75

10080

88

38

10.000

10.0

.3937

Fresa sub-micrograno metallo duro - taglio al centro

86360

11.113

2-1/2"

9/16"

.4375

Alte prestazioni per lavorazioni di acciai, inox e materiali esotici

2-3/4"

7/16"

.4375

7/16"

86370

1"

11.113

Serraggio rigido, macchina stabile e ottimo bloccaggio del pezzo sono necessari!

4"

Consigliata per una migliore finitura sul titanio

16

12.0

12.000

.4724

65

10090

Nocciolo rinforzato

26

75

12.000

.4724

10100

12.0

Tagliente vivo

12.0

Rivestimento in AlTiN - Pagina 178 86380 .4375 7/16" 11.113 7/16" 100 2"

10110

.4724

50

12.000

Rivestimento in TiCN - Pagina 182 86400 .5000 1/2" 12.700 1/2" 2-1/2" 5/8"

86420 .5000 1/2" 12.700 1/2" 3" 1"

86440 .5000 1/2" 12.700 1/2" 4" 2"

高效超细晶粒整体硬质合金立铣刀 - 中心切削 10430 .5512 14.000 14.0 65 16

在钢件、不锈钢和稀有材质上作高效铣削

高刚性工件夹持、机床稳定性以及零件的牢固性是至关重要的因素! 10440 .5512 14.000 14.0 75 25

0 改善钛合金的光洁度 10450 .5512 14.000 14.0 100 50

强力芯部

6

尖角

AlTiN 涂层 - 178页

TiCN 涂层 - 182页

180 www.garrtool.com ® ® ® † Metric equivalents are for reference only