Page 255 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 255

USER GUIDE

Technical Information -

Cartridge Style Counter Boring Head Diameter Settings

The drill head diameter is set and inspected with a master insert in our final inspection.

However, the inserts in the market have a tolerance fluctuation so each time you change or

index the insert, the diameter must be adjusted as per the following method.

Note: When a corner change is made on the insert, it must be adjusted to the correct

size or damage can be caused to the head body or work piece material.

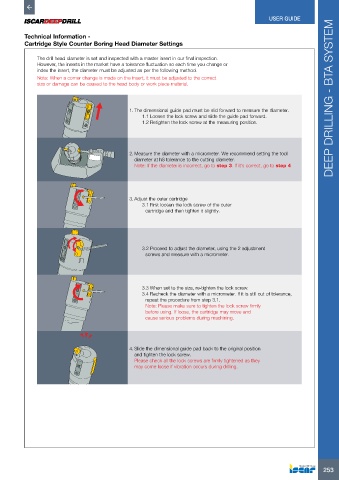

1. The dimensional guide pad must be slid forward to measure the diameter. DEEP DRILLING - BTA SYSTEM

1.1 Loosen the lock screw and slide the guide pad forward.

1.2 Retighten the lock screw at the measuring position.

2. Measure the diameter with a micrometer. We recommend setting the tool

diameter at h8 tolerance to the cutting diameter.

Note: If the diameter is incorrect, go to step 3. If it’s correct, go to step 4

3. Adjust the outer cartridge

3.1 First loosen the lock screw of the outer

cartridge and then tighten it slightly.

3.2 Proceed to adjust the diameter, using the 2 adjustment

screws and measure with a micrometer.

3.3 When set to the size, re-tighten the lock screw.

3.4 Recheck the diameter with a micrometer. If it is still out of tolerance,

repeat the procedure from step 3.1.

Note: Please make sure to tighten the lock screw firmly

before using. If loose, the cartridge may move and

cause serious problems during machining.

4. Slide the dimensional guide pad back to the original position

and tighten the lock screw.

Please check all the lock screws are firmly tightened as they

may come loose if vibration occurs during drilling.

253