Page 285 - ISCAR(MILLINGCATALOG 38_2021)

P. 285

DRVS

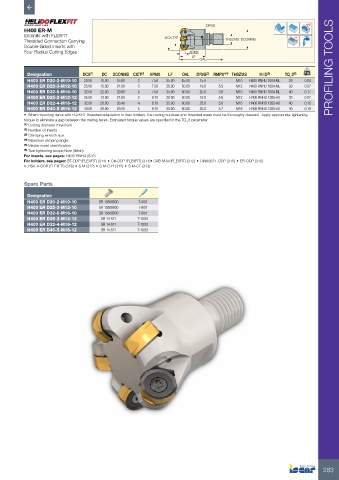

H400 ER-M

Endmills with FLEXFIT DCX DC Rd°

Threaded Connection Carrying THSZMS DCONMS

Double-Sided Inserts with

Four Radius Cutting Edges APMX

LF

OAL

Designation DCX (1) DC DCONMS CICT (2) APMX LF OAL DRVS (3) RMPX° (4) THSZMS MIID (5) TQ_3 (6) kg PROFILING TOOLS

H400 ER D20-2-M10-10 20.00 10.00 16.60 2 7.50 25.00 45.00 15.0 - M10 H400 RNHU 1004-ML 29 0.04

H400 ER D25-3-M12-10 25.00 15.00 21.00 3 7.50 28.00 50.00 19.0 5.8 M12 H400 RNHU 1004-ML 33 0.07

H400 ER D32-5-M16-10 32.00 22.00 29.60 5 7.50 35.00 60.00 25.0 3.8 M16 H400 RNHU 1004-ML 40 0.17

H400 ER D25-2-M12-12 25.00 13.00 21.60 2 8.70 28.00 50.00 19.0 5.6 M12 H400 RNHU 1205-AX 33 0.07

H400 ER D32-4-M16-12 32.00 20.00 28.40 4 8.70 35.00 60.00 25.0 5.6 M16 H400 RNHU 1205-AX 40 0.15

H400 ER D40-5-M16-12 40.00 28.00 29.00 5 8.70 35.00 60.00 25.0 3.7 M16 H400 RNHU 1205-AX 40 0.19

• When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces and threaded areas must be thoroughly cleaned. Apply appropriate tightening

torque to eliminate a gap between the mating faces. Estimated torque values are specified in the TQ_3 parameter

(1) Cutting diameter maximum

(2) Number of inserts

(3) Clamping wrench size

(4) Maximum ramping angle

(5) Master insert identification

(6) Tool tightening torque Nxm (lbfxin)

For inserts, see pages: H400 RNHU (532)

For holders, see pages: BT-ODP (FLEXFIT) (314) • C#-ODP (FLEXFIT) (314)• CAB M-M (FLEXFIT) (312) • DIN69871-ODP (315) • ER-ODP (315)

• HSK A-ODP (FLEXFIT) (316) • S M (312) • S M-C-H (312) • S M-CF (313)

Spare Parts

Designation

H400 ER D20-2-M10-10 SR 10508600 T-9/51

H400 ER D25-3-M12-10 SR 10508600 T-9/51

H400 ER D32-5-M16-10 SR 10508600 T-9/51

H400 ER D25-2-M12-12 SR 14-571 T-10/51

H400 ER D32-4-M16-12 SR 14-571 T-10/51

H400 ER D40-5-M16-12 SR 14-571 T-10/51

283