Page 289 - ISCAR(MILLINGCATALOG 38_2021)

P. 289

USER GUIDE

PROFILING TOOLS

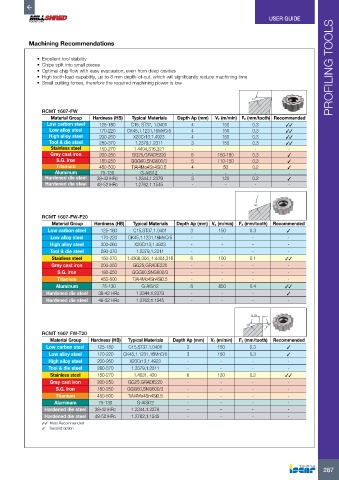

Machining Recommendations

• Excellent tool stability

• Chips split into small pieces

• Optimal chip flow with easy evacuation, even from deep cavities

• High tooth load capability, up to 8 mm depth-of-cut, which will significantly reduce machining time

• Small cutting forces, therefore the required machining power is low

12˚

RCMT 1607-FW

Material Group Hardness (HB) Typical Materials Depth Ap (mm) Vc (m/min) Fz (mm/tooth) Recommended

Low carbon steel 125-180 C15, ST37, 1.0401 4 150 0.3 33

Low alloy steel 170-220 CK45,1.1231,16MnCr5 4 150 0.3 33

High alloy steel 200-260 X20Cr13,1.4923 4 150 0.3 33

Tool & die steel 280-370 1.2379,1.2311 3 150 0.3 33

Stainless steel 150-270 1.4404,316,321 - - - -

Grey cast iron 200-250 GG25,GRADE220 5 150-180 0.3 3

S.G. iron 180-250 GGG60,SNG600/3 5 110-150 0.3 3

Titanium 450-500 TiAI4Mo4Sn4Si0.5 4 50 0.2 3

Aluminum 75-130 G-AISi12 - - - -

Hardened die steel 38-42 HRc 1.2344,1.2379 3 120 0.2 3

Hardened die steel 48-52 HRc 1.2762,1.1545 - - - -

20˚

RCMT 1607-FW-F20

Material Group Hardness (HB) Typical Materials Depth Ap (mm) Vc (m/min) Fz (mm/tooth) Recommended

Low carbon steel 125-180 C15,ST37,1.0401 3 150 0.3 3

Low alloy steel 170-220 CK45,1.1231,16MnCr5 - - - -

High alloy steel 200-260 X20Cr13,1.4923 - - - -

Tool & die steel 280-370 1.2379,1.2311 - - - -

Stainless steel 150-270 1.4306,304, 1.4404,316 6 100 0.1 33

Grey cast iron 200-250 GG25,GRADE220 - - - -

S.G. iron 180-250 GGG60,SNG600/3 - - - -

Titanium 450-500 TiAI4Mo4Sn4Si0.5 - - - -

Aluminum 75-130 G-AISi12 6 850 0.4 33

Hardened die steel 38-42 HRc 1.2344,1.2379 - - - 3

Hardened die steel 48-52 HRc 1.2762,1.1545 - - - -

0.15

20˚ 20˚

RCMT 1607 FW-T20

Material Group Hardness (HB) Typical Materials Depth Ap (mm) Vc (m/min) Fz (mm/tooth) Recommended

Low carbon steel 125-180 C15,ST37,1.0401 3 150 0.3 3

Low alloy steel 170-220 CK45,1.1231,16MnCr5 3 150 0.3 3

High alloy steel 200-260 X20Cr13,1.4923 - - - -

Tool & die steel 280-370 1.2379,1.2311 - - - -

Stainless steel 150-270 1.4031, 420 6 120 0.2 33

Grey cast iron 200-250 GG25,GRADE220 - - - -

S.G. iron 180-250 GGG60,SNG600/3 - - - -

Titanium 450-500 TiAI4Mo4Sn4Si0.5 - - - -

Aluminum 75-130 G-AISi12 - - - -

Hardened die steel 38-42 HRc 1.2344,1.2379 - - - -

Hardened die steel 48-52 HRc 1.2762,1.1545 - - - -

33 Most Recommended

3 Second option

287