Page 392 - ISCAR(MILLINGCATALOG 38_2021)

P. 392

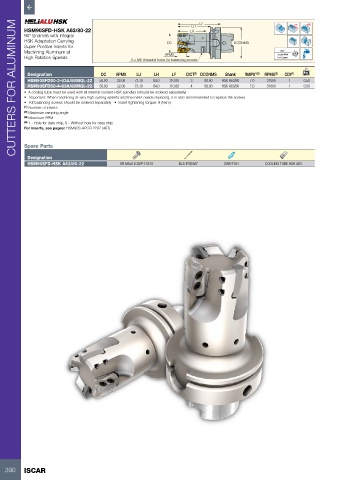

CUTTERS FOR ALUMINUM

LF

LH Rd°

HSM90SFD-HSK A63/80-22 LU

90° Endmills with Integral

HSK Adaptation Carrying DC DCONMS

Super Positive Inserts for

Machining Aluminum at APMX G2.5

High Rotation Speeds 6 x M6 threaded holes for balancing screws 31,000 RPM

U<1.0 gmm

Designation DC APMX LU LH LF CICT (1) DCONMS Shank RMPX° (2) RPMX (3) CDI (4) kg

HSM90SFD50-3-63A/80MQL-22 50.00 22.00 73.10 84.0 110.00 3 80.00 HSK A63/80 7.0 31000 1 0.50

HSM90SFD50-4-63A/80MQL-22 50.00 22.00 73.10 84.0 110.00 4 80.00 HSK A63/80 7.0 31000 1 0.50

• A cooling tube must be used with all internal coolant HSK spindles (should be ordered separately)

• Important: When machining at very high cutting speeds and the insert needs replacing, it is also recommended to replace the screws

• Kit balancing screws should be ordered separately • Insert tightening torque: 9 (Nxm)

(1) Number of inserts

(2) Maximum ramping angle

(3) Maximum RPM

(4) 1 - Hole for data chip, 0 - Without hole for data chip

For inserts, see pages: HSM90S APCR 2207 (467)

Spare Parts

Designation

HSM90SFD-HSK A63/80-22 SR M5x0.8 20IP-13343 BLD IP20/M7 SW6-T-SH COOLING TUBE HSK A63

390 ISCAR