Page 56 - ISCAR(MILLINGCATALOG 38_2021)

P. 56

MM TS077-N...

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

15

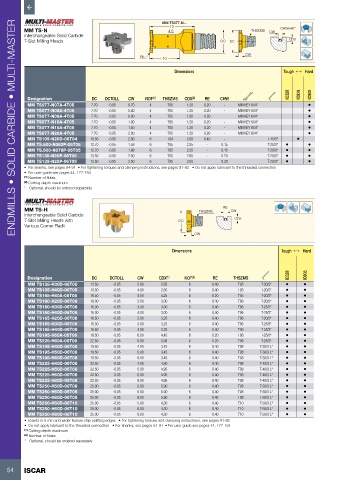

MM TS-N 4.5 THSZMS CW CHWx45°

Interchangeable Solid Carbide

T-Slot Milling Heads 8.0 DC CDX

RE CW

10

Dimensions Tough 1 Hard

IC328 IC928 IC908

Designation DC DCTOLL CW NOF (1) THSZMS CDX (2) RE CHW

MM TS077-N07A-4T05 7.70 -0.05 0.70 4 T05 1.20 0.20 - MM KEY 6X4* •

MM TS077-N08A-4T05 7.70 -0.05 0.80 4 T05 1.20 0.20 - MM KEY 6X4* •

MM TS077-N09A-4T05 7.70 -0.05 0.90 4 T05 1.20 0.20 - MM KEY 6X4* •

MM TS077-N10A-4T05 7.70 -0.05 1.00 4 T05 1.20 0.20 - MM KEY 6X4* •

MM TS077-N15A-4T05 7.70 -0.05 1.50 4 T05 1.20 0.20 - MM KEY 6X4* •

MM TS077-N20A-4T05 7.70 -0.05 2.00 4 T05 1.20 0.20 - MM KEY 6X4* •

MM TS105-N20D-06T04 10.50 -0.05 2.00 6 T04 2.00 0.40 - T-15/3* •

MM TS.500-N062P-06T05 12.70 -0.05 1.58 6 T05 2.25 - 0.15 T-20/3* • •

MM TS.500-N078P-06T05 12.70 -0.05 1.98 6 T05 2.25 - 0.15 T-20/3* • •

MM TS135-N20P-06T05 13.50 -0.05 2.00 6 T05 2.65 - 0.20 T-20/3* • •

MM TS135-N25P-06T05 13.50 -0.05 2.50 6 T05 2.65 - 0.20 T-20/3* • •

• For shanks, see pages 84-91 • For tightening torques and clamping instructions, see pages 91-92 • Do not apply lubricant to the threaded connection

• For user guide see pages 44, 177-184

(1) Number of flutes

(2) Cutting depth maximum

* Optional, should be ordered separately

MM TS-H THSZMS RE CW

Interchangeable Solid Carbide

T-Slot Milling Heads with DC CDX

Various Corner Radii

CW

Dimensions Tough 1 Hard

IC328 IC908

Designation DC DCTOLL CW CDX (1) NOF (2) RE THSZMS

MM TS135-H30D-06T05 13.50 -0.05 3.00 2.65 6 0.40 T05 T-20/3* • •

MM TS135-H40D-06T05 13.50 -0.05 4.00 2.65 6 0.40 T05 T-20/3* • •

MM TS165-H40A-06T05 16.50 -0.05 4.00 4.25 6 0.20 T05 T-20/3* • •

MM TS160-H20D-06T06 16.00 -0.05 2.00 3.00 6 0.40 T06 T-20/3* • •

MM TS160-H30D-06T06 16.00 -0.05 3.00 3.00 6 0.40 T06 T-25/3* • •

MM TS160-H40D-06T06 16.00 -0.05 4.00 3.00 6 0.40 T06 T-25/3* • •

MM TS165-H20D-06T06 16.50 -0.05 2.00 3.25 6 0.40 T06 T-20/3* • •

MM TS165-H30D-06T06 16.50 -0.05 3.00 3.25 6 0.40 T06 T-25/3* • •

MM TS165-H40D-06T06 16.50 -0.05 4.00 3.25 6 0.40 T06 T-25/3* • •

MM TS195-H60A-06T06 19.50 -0.05 6.00 4.45 6 0.20 T06 T-25/3* • •

MM TS225-H60A-06T06 22.50 -0.05 6.00 5.95 6 0.20 T06 T-25/3* • •

MM TS195-H40D-06T08 19.50 -0.05 4.00 3.45 6 0.40 T08 T-30/3 L* • •

MM TS195-H50D-06T08 19.50 -0.05 5.00 3.45 6 0.40 T08 T-30/3 L* • •

MM TS195-H60D-06T08 19.50 -0.05 6.00 3.45 6 0.40 T08 T-30/3 L* • •

MM TS225-H40D-06T08 22.50 -0.05 4.00 4.90 6 0.40 T08 T-40/3 L* • •

MM TS225-H50D-06T08 22.50 -0.05 5.00 4.95 6 0.40 T08 T-40/3 L* • •

MM TS225-H60D-06T08 22.50 -0.05 6.00 4.95 6 0.40 T08 T-40/3 L* • •

MM TS225-H80D-06T08 22.50 -0.05 8.00 4.95 6 0.40 T08 T-40/3 L* • •

MM TS250-H50D-06T08 25.00 -0.05 5.00 5.90 6 0.40 T08 T-50/3 L* • •

MM TS250-H60D-06T08 25.00 -0.05 6.00 5.90 6 0.40 T08 T-50/3 L* • •

MM TS250-H80D-06T08 25.00 -0.05 8.00 5.90 6 0.40 T08 T-50/3 L* • •

MM TS250-H50D-06T10 25.00 -0.05 5.00 4.30 6 0.40 T10 T-50/3 L* • •

MM TS250-H60D-06T10 25.00 -0.05 6.00 4.30 6 0.40 T10 T-50/3 L* • •

MM TS250-H80D-06T10 25.00 -0.05 8.00 4.30 6 0.40 T10 T-50/3 L* • •

• Inserts in 5 mm and wider feature chip splitting edges • For tightening torques and clamping instructions, see pages 91-92

• Do not apply lubricant to the threaded connection • For shanks, see pages 84-91 • For user guide see pages 44, 177-184

(1) Cutting depth maximum

(2) Number of flutes

* Optional, should be ordered separately

54 ISCAR