Page 59 - ISCAR(MILLINGCATALOG 38_2021)

P. 59

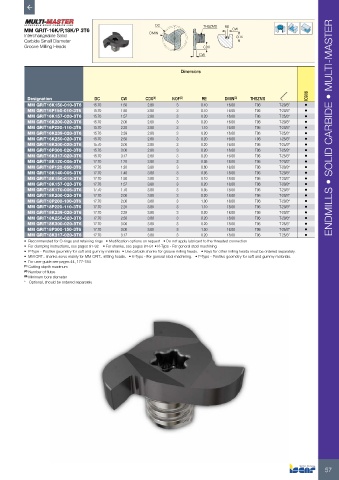

MM GRIT-16K/P,18K/P 3T6 DC THSZMS RE CW

Interchangeable Solid DMIN CDX

Carbide Small Diameter

Groove Milling Heads CDX

CW

Dimensions

IC908

Designation DC CW CDX (1) NOF (2) RE DMIN (3) THSZMS

MM GRIT16K150-010-3T6 15.70 1.50 2.80 3 0.10 16.00 T06 T-20/3* •

MM GRIT16P150-010-3T6 15.70 1.50 2.80 3 0.10 16.00 T06 T-20/3* •

MM GRIT16K157-020-3T6 15.70 1.57 2.80 3 0.20 16.00 T06 T-25/3* •

MM GRIT16K200-020-3T6 15.70 2.00 2.80 3 0.20 16.00 T06 T-20/3* •

MM GRIT16P220-110-3T6 15.70 2.20 2.80 3 1.10 16.00 T06 T-20/3* • ENDMILLS • SOLID CARBIDE • MULTI-MASTER

MM GRIT16K239-020-3T6 15.70 2.39 2.80 3 0.20 16.00 T06 T-25/3* •

MM GRIT16K250-020-3T6 15.70 2.50 2.80 3 0.20 16.00 T06 T-25/3* •

MM GRIT16K300-020-3T6 15.70 3.00 2.80 3 0.20 16.00 T06 T-25/3* •

MM GRIT16P300-020-3T6 15.70 3.00 2.80 3 0.20 16.00 T06 T-25/3* •

MM GRIT16K317-020-3T6 15.70 3.17 2.80 3 0.20 16.00 T06 T-25/3* •

MM GRIT18K120-005-3T6 17.70 1.20 3.80 3 0.05 18.00 T06 T-20/3* •

MM GRIT18P120-060-3T6 17.70 1.20 3.80 3 0.60 18.00 T06 T-20/3* •

MM GRIT18K140-005-3T6 17.70 1.40 3.80 3 0.05 18.00 T06 T-20/3* •

MM GRIT18K150-010-3T6 17.70 1.50 3.80 3 0.10 18.00 T06 T-20/3* •

MM GRIT18K157-020-3T6 17.70 1.57 3.80 3 0.20 18.00 T06 T-20/3* •

MM GRIT18K170-005-3T6 17.70 1.70 3.80 3 0.05 18.00 T06 T-20/3* •

MM GRIT18K200-020-3T6 17.70 2.00 3.80 3 0.20 18.00 T06 T-20/3* •

MM GRIT18P200-100-3T6 17.70 2.00 3.80 3 1.00 18.00 T06 T-20/3* •

MM GRIT18P220-110-3T6 17.70 2.20 3.80 3 1.10 18.00 T06 T-20/3* •

MM GRIT18K239-020-3T6 17.70 2.39 3.80 3 0.20 18.00 T06 T-20/3* •

MM GRIT18K250-020-3T6 17.70 2.50 3.80 3 0.20 18.00 T06 T-20/3* •

MM GRIT18K300-020-3T6 17.70 3.00 3.80 3 0.20 18.00 T06 T-25/3* •

MM GRIT18P300-150-3T6 17.70 3.00 3.80 3 1.50 18.00 T06 T-25/3* •

MM GRIT18K317-020-3T6 17.70 3.17 3.80 3 0.20 18.00 T06 T-25/3* •

• Recommended for O-rings and retaining rings • Modification options on request • Do not apply lubricant to the threaded connection

• For clamping instructions, see pages 91-92 • For shanks, see pages 84-91 • K-Type - For general steel machining

• P-Type - Positive geometry for soft and gummy materials • Use carbide shanks for groove milling heads. • Keys for other milling heads must be ordered separately.

• MM GRT.. shanks serve mainly for MM GRIT.. slitting heads. • K-Type - For general steel machining. • P-Type - Positive geometry for soft and gummy materials.

• For user guide see pages 44, 177-184

(1) Cutting depth maximum

(2) Number of flutes

(3) Minimum bore diameter

* Optional, should be ordered separately

57