Page 615 - ISCAR(MILLINGCATALOG 38_2021)

P. 615

USER GUIDE

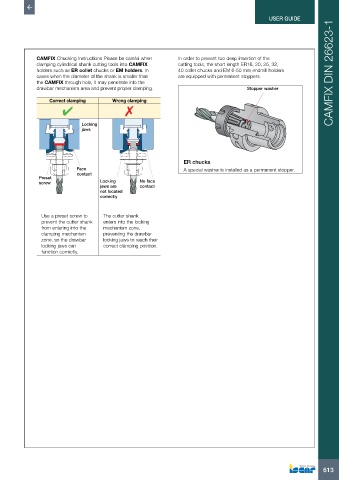

CAMFIX Chucking Instructions Please be careful when In order to prevent too deep insertion of the

clamping cylindrical shank cutting tools into CAMFIX cutting tools, the short length ER16, 20, 25, 32,

holders such as ER collet chucks or EM holders. In 40 collet chucks and EM 6-50 mm endmill holders

cases when the diameter of the shank is smaller than are equipped with permanent stoppers. CAMFIX DIN 26623-1

the CAMFIX through hole, it may penetrate into the

drawbar mechanism area and prevent proper clamping. Stopper washer

Correct clamping Wrong clamping

4 7

Locking

jaws

ER chucks

Face A special washer is installed as a permanent stopper.

contact

Preset

screw Locking No face

jaws are contact

not located

correctly

Use a preset screw to The cutter shank

prevent the cutter shank enters into the locking

from entering into the mechanism zone,

clamping mechanism preventing the drawbar

zone, so the drawbar locking jaws to reach their

locking jaws can correct clamping position.

function correctly.

613