Page 264 - ISCAR(TURNING-CATALOG-42-2022)

P. 264

SELECTION GUIDE

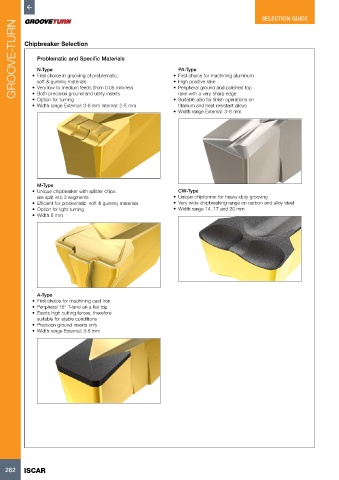

GROOVE-TURN Chipbreaker Selection • First choice for machining aluminum

Problematic and Specific Materials

N-Type

PA-Type

• First choice in grooving of problematic,

• High positive rake

soft & gummy materials

• Very low to medium feeds (from 0.05 mm/rev)

rake with a very sharp edge

• Both precision ground and utility inserts

• Option for turning

• Suitable also for finish operations on

titanium and heat resistant alloys

• Width range External: 3-8 mm Internal: 2-5 mm • Peripheral ground and polished top

• Width range External: 3-8 mm

M-Type

• Unique chipbreaker with splitter chips CW-Type

are split into 3 segments • Unique chipformer for heavy-duty grooving

• Efficient for problematic, soft & gummy materials • Very wide chipbreaking range on carbon and alloy steel

• Option for light turning • Width range 14, 17 and 20 mm

• Width 8 mm

A-Type

• First choice for machining cast Iron

• Peripheral 15° T-land on a flat top

• Exerts high cutting forces, therefore

suitable for stable conditions

• Precision ground inserts only

• Width range External: 3-8 mm

262 ISCAR