Page 324 - ISCAR(TURNING-CATALOG-42-2022)

P. 324

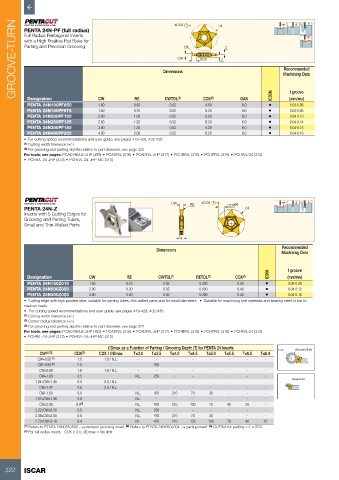

GROOVE-TURN PENTA 24N-PF (full radius) Dimensions RE CDX 24 2 2 Recommended

±0.04

Full Radius Pentagonal Inserts

with a High Positive Flat Rake for

Parting and Precision Grooving

CW

Machining Data

f groove

RE

Designation

PENTA 24N100PF050 CW 0.50 CWTOL (1) CDX (2) GAN • IC30N (mm/rev)

0.02

0.03-0.06

6.0

1.00

4.50

PENTA 24N150PF075 1.50 0.75 0.02 6.20 6.0 • 0.03-0.06

PENTA 24N200PF100 2.00 1.00 0.02 6.20 6.0 • 0.04-0.10

PENTA 24N250PF125 2.50 1.25 0.02 6.20 6.0 • 0.04-0.14

PENTA 24N300PF150 3.00 1.50 0.02 6.20 6.0 • 0.04-0.15

PENTA 24N400PF200 4.00 2.00 0.02 6.20 6.0 • 0.04-0.16

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) For grooving and parting depths relative to part diameter, see page 322

For tools, see pages: PCAD RE/LE-JHP (499) • PCADR/L (316) • PCADR/L-JHP (317) • PCHBR/L (318) • PCHPR/L (316) • PCHR/L-24 (312)

• PCHR/L-24-JHP (313) • PCHR/L-24-JHP-MC (313)

CW ±0.04

PENTA 24N-Z RE CDX (3) 24

Inserts with 5 Cutting Edges for

Grooving and Parting Tubes,

Small and Thin-Walled Parts

4

Dimensions Recommended

Machining Data

IC908 f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) (mm/rev)

PENTA 24N150Z010 1.50 0.10 0.02 0.020 5.00 • 0.05-0.08

PENTA 24N200Z020 2.00 0.20 0.02 0.030 6.40 • 0.04-0.12

PENTA 24N300Z020 3.00 0.20 0.02 0.000 6.40 • 0.04-0.16

• Cutting edge with high positive rake, suitable for parting tubes, thin walled parts and for small diameters • Suitable for machining soft materials and bearing steel at low to

medium feeds

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) For grooving and parting depths relative to part diameter, see page 322

For tools, see pages: PCAD RE/LE-JHP (499) • PCADR/L (316) • PCADR/L-JHP (317) • PCHBR/L (318) • PCHPR/L (316) • PCHR/L-24 (312)

• PCHR/L-24-JHP (313) • PCHR/L-24-JHP-MC (313)

ØDmax as a Function of Parting / Grooving Depth (T) for PENTA 24 Inserts Tmax ØDmax(CUTDIA)

CW ±0.02 CDX (3) CDX / ØDmax T≤3.0 T≤3.5 T≤4.0 T≤4.5 T≤5.0 T≤5.5 T≤6.5 T≤6.4

CW=0.50 (1) 1.0 1.0 / N.L. - - - - - - - -

CW=0.50 (2) 2.5 250

CW=0.80 1.6 1.6 / N.L. - - - - - - - -

CW=1.00 3.5 N.L. 250 - - - - - -

ØDmax(CUTDIA)

1.04≤CW≤1.40 2.0 2.0 / N.L. - - - - - - - -

CW=1.47 2.5 2.5 / N.L. - - - - - - - -

CW=1.50 5.0 N.L. 470 210 70 30 - - -

1.57≤CW≤1.96 3.0 N.L. - - - - - - -

CW=2.00 6.0 (4) N.L. 470 210 130 75 45 20 -

2.22≤CW≤2.30 3.5 N.L. 250 - - - - - -

2.39≤CW≤2.50 5.0 N.L. 470 210 70 30 - - -

2.70≤CW≤3.18 6.4 N.L. 470 210 135 100 70 40 20

(1) Refers to PENTA 24N050J000 - a precision grooving insert (2) Refers to PENTA 24N050J004 - a parting insert (3) CUTDIA for parting = 2 x CDX

For full radius insert, CDX = 3.0, ØDmax = No limit

(4)

322 ISCAR