Page 328 - ISCAR(TURNING-CATALOG-42-2022)

P. 328

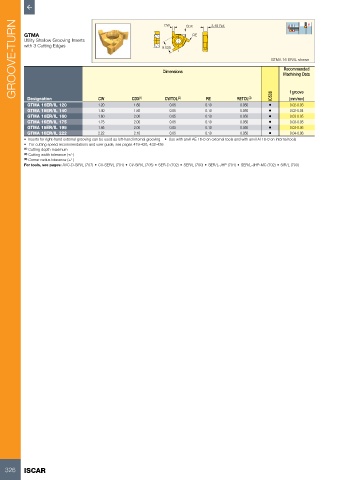

GROOVE-TURN GTMA 9.525 CDX RE 3.48 Ref. GTMA 16 ER/IL shown

CW

Utility Shallow Grooving Inserts

with 3 Cutting Edges

Recommended

Dimensions

Machining Data

f groove

Designation

RE

GTMA 16ER/IL 120 CW CDX (1) CWTOL (2) 0.10 RETOL (3) • IC508 (mm/rev)

0.02-0.03

1.60

1.20

0.050

0.05

GTMA 16ER/IL 140 1.40 1.80 0.05 0.10 0.050 • 0.02-0.04

GTMA 16ER/IL 160 1.60 2.00 0.05 0.10 0.050 • 0.03-0.05

GTMA 16ER/IL 175 1.75 2.00 0.05 0.10 0.050 • 0.03-0.05

GTMA 16ER/IL 195 1.95 2.00 0.05 0.10 0.050 • 0.03-0.06

GTMA 16ER/IL 222 2.22 2.10 0.05 0.10 0.050 • 0.04-0.06

• Inserts for right-hand external grooving can be used as left-hand internal grooving • Use with anvil AE 16-0 on external tools and with anvil AI 16-0 on internal tools

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting depth maximum

(2) Cutting width tolerance (+/-)

(3) Corner radius tolerance (+/-)

For tools, see pages: AVC-D-SIR/L (707) • C#-SER/L (701) • C#-SIR/L (705) • SER-D (702) • SER/L (700) • SER/L-JHP (701) • SER/L-JHP-MC (702) • SIR/L (703)

326 ISCAR