Page 331 - ISCAR(TURNING-CATALOG-42-2022)

P. 331

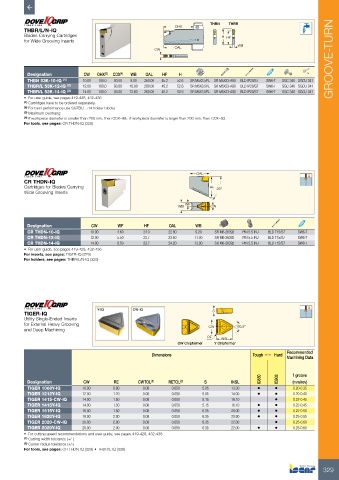

THBN THBR

THBR/L/N-IQ OHX

Blades Carrying Cartridges H HF

for Wide Grooving Inserts

WB

OAL

CW GROOVE-TURN

Designation CW OHX (3) CDX (4) WB OAL HF H

THBN 53K-10-IQ (1) 10.00 100.0 93.00 9.00 260.00 45.2 52.6 SR M5X3.5PL SR M5X23-A90 BLD IP20/S7 SW6-T SGC 340 SGCU 341

THBR/L 53K-12-IQ (2) 12.00 100.0 93.00 10.80 260.00 45.2 52.6 SR M5X3.5PL SR M5X23-A90 BLD IP20/S7 SW6-T SGC 340 SGCU 341

THBR/L 53K-14-IQ (2) 14.00 100.0 93.00 12.60 260.00 45.2 52.6 SR M5X3.5PL SR M5X23-A90 BLD IP20/S7 SW6-T SGC 340 SGCU 341

• For user guide, see pages 419-428, 432-436

(1) Cartridges have to be ordered separately.

(2) For best performance use SGTBU...-14 holder blocks

(3) Maximum overhang

(4) If workpiece diameter is smaller than 200 mm, then CDX=98, if workpiece diameter is larger than 200 mm, then CDX=93.

For tools, see pages: CR THDN-IQ (329)

OAL

CR THDN-IQ

Cartridges for Blades Carrying HF 25°

Wide Grooving Inserts

WF

WB CW

Designation CW WF HF OAL WB

CR THDN-10-IQ 10.00 4.60 24.0 22.60 9.20 SR M6-26392 PIN 5.5 INJ BLD T15/S7 SW6-T

CR THDN-12-IQ 12.00 5.50 23.7 23.60 11.00 SR M6-26392 PIN 5.5 INJ BLD T15/S7 SW6-T

CR THDN-14-IQ 14.00 6.50 23.7 24.20 13.00 SR M6-26392 PIN 5.5 INJ BLD T15/S7 SW6-T

• For user guide, see pages 419-428, 432-436

For inserts, see pages: TIGER-IQ (329)

For holders, see pages: THBR/L/N-IQ (329)

TIGER-IQ S

Utility Single-Ended Inserts

for External Heavy Grooving CW 60.5°

and Deep Machining

RE INSL

CW Chipformer Y Chipformer

Recommended

Dimensions Tough 1 Hard

Machining Data

f groove

Designation CW RE CWTOL (1) RETOL (2) S INSL IC830 IC808 (mm/rev)

TIGER 1008Y-IQ 10.00 0.80 0.08 0.050 5.05 13.30 • • 0.20-0.35

TIGER 1212Y-IQ 12.00 1.20 0.08 0.050 5.05 14.00 • • 0.20-0.40

TIGER 1415-CW-IQ 14.00 1.50 0.08 0.050 5.15 16.10 • 0.22-0.45

TIGER 1415Y-IQ 14.00 1.50 0.08 0.050 5.15 16.10 • • 0.22-0.45

TIGER 1615Y-IQ 16.00 1.50 0.08 0.050 6.35 20.00 • • 0.22-0.50

TIGER 1820Y-IQ 18.00 2.00 0.08 0.050 6.35 20.90 • • 0.25-0.55

TIGER 2020-CW-IQ 20.00 2.00 0.08 0.050 6.35 22.00 • 0.25-0.60

TIGER 2020Y-IQ 20.00 2.00 0.08 0.050 6.35 22.00 • • 0.25-0.60

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: CR THDN-IQ (329) • THDR/L-IQ (328)

329