Page 326 - ISCAR(TURNING-CATALOG-42-2022)

P. 326

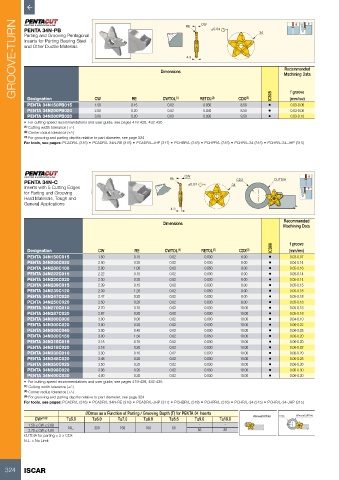

GROOVE-TURN PENTA 34N-PB Dimensions RE CW ±0.04 34 Machining Data

Parting and Grooving Pentagonal

Inserts for Parting Bearing Steel

and Other Ductile Materials

4.3

Recommended

f groove

Designation

RE

PENTA 34N150PB015 CW 0.15 CWTOL (1) RETOL (2) CDX (3) • IC908 (mm/rev)

8.50

1.50

0.02

0.030

0.03-0.06

PENTA 34N200PB020 2.00 0.20 0.02 0.030 8.50 • 0.03-0.08

PENTA 34N300PB020 3.00 0.20 0.02 0.030 9.50 • 0.03-0.10

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) For grooving and parting depths relative to part diameter, see page 324

For tools, see pages: PCADR/L (316) • PCADR/L 34N-RE (318) • PCADR/L-JHP (317) • PCHBR/L (318) • PCHPR/L (316) • PCHR/L-34 (315) • PCHR/L-34-JHP (315)

CW

PENTA 34N-C RE ±0.04 34 CDX CUTDIA

Inserts with 5 Cutting Edges

for Parting and Grooving

Hard Materials, Tough and

General Applications

4.3

Recommended

Dimensions Machining Data

IC908 f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) (mm/rev)

PENTA 34N150C015 1.50 0.15 0.02 0.030 8.00 • 0.03-0.07

PENTA 34N200C020 2.00 0.20 0.02 0.030 8.00 • 0.04-0.14

PENTA 34N200C100 2.00 1.00 0.02 0.050 8.00 • 0.05-0.16

PENTA 34N222C015 2.22 0.15 0.02 0.030 8.00 • 0.05-0.14

PENTA 34N230C020 2.30 0.20 0.02 0.030 8.00 • 0.05-0.14

PENTA 34N239C015 2.39 0.15 0.02 0.030 8.00 • 0.05-0.15

PENTA 34N239C120 2.39 1.20 0.02 0.050 8.00 • 0.05-0.18

PENTA 34N247C020 2.47 0.20 0.02 0.030 8.00 • 0.05-0.18

PENTA 34N250C020 2.50 0.20 0.02 0.030 8.00 • 0.05-0.18

PENTA 34N270C010 2.70 0.10 0.02 0.030 10.00 • 0.05-0.18

PENTA 34N287C020 2.87 0.20 0.02 0.030 10.00 • 0.05-0.18

PENTA 34N300C000 3.00 0.00 0.02 0.000 10.00 • 0.04-0.10

PENTA 34N300C020 3.00 0.20 0.02 0.030 10.00 • 0.06-0.22

PENTA 34N300C040 3.00 0.40 0.02 0.030 10.00 • 0.06-0.25

PENTA 34N300C150 3.00 1.50 0.02 0.050 10.00 • 0.06-0.20

PENTA 34N315C015 3.15 0.15 0.02 0.030 10.00 • 0.06-0.20

PENTA 34N318C020 3.18 0.20 0.02 0.030 10.00 • 0.06-0.22

PENTA 34N330C010 3.30 0.10 0.02 0.020 10.00 • 0.06-0.20

PENTA 34N348C020 3.48 0.20 0.02 0.030 10.00 • 0.06-0.25

PENTA 34N350C025 3.50 0.25 0.02 0.030 10.00 • 0.06-0.30

PENTA 34N398C020 3.98 0.20 0.02 0.030 10.00 • 0.06-0.30

PENTA 34N400C030 4.00 0.30 0.02 0.030 10.00 • 0.06-0.30

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) For grooving and parting depths relative to part diameter, see page 324

For tools, see pages: PCADR/L (316) • PCADR/L 34N-RE (318) • PCADR/L-JHP (317) • PCHBR/L (318) • PCHPR/L (316) • PCHR/L-34 (315) • PCHR/L-34-JHP (315)

ØDmax as a Function of Parting / Grooving Depth (T) for PENTA 34 Inserts ØDmax(CUTDIA)

CW ±0.02 T≤5.0 T≤6.0 T≤7.0 T≤8.0 T≤8.5 T≤9.0 T≤10.0 ØDmax(CUTDIA) Tmax

1.50 ≤ CW ≤ 2.69 - -

2.70 ≤ CW ≤ 4.00 N.L. 350 165 100 55 55 20

CUTDIA for parting = 2 x CDX

N.L. = No Limit

324 ISCAR