Page 336 - ISCAR(TURNING-CATALOG-42-2022)

P. 336

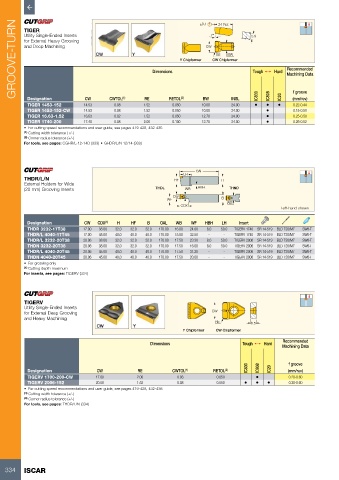

GROOVE-TURN TIGER Dimensions Y Chipformer ±0.1 CW 7° CW Chipformer 5.9 Recommended

24 Ref.

Utility Single-Ended Inserts

for External Heavy Grooving

and Deep Machining

BW

RE

Tough 1 Hard

Machining Data

f groove

BW

CW

RE

Designation

0.050

0.22-0.44

0.08

TIGER 1453-152 14.53 CWTOL (1) 1.52 RETOL (2) 10.00 INSL • IC830 • IC808 • IC20 (mm/rev)

24.00

TIGER 1453-152-CW 14.53 0.08 1.52 0.050 10.00 24.00 • 0.15-0.50

TIGER 16.63-1.52 16.63 0.02 1.52 0.050 12.70 24.00 • 0.25-0.50

TIGER 1740-200 17.40 0.08 2.00 0.100 12.70 24.00 • 0.26-0.52

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: CGHR/L-12-14D (333) • GHDR/L/N 12/14 (333)

OAL

THDR/L/N HF LH H

External Holders for Wide

(20 mm) Grooving Inserts THDL WB HBH THND

CW B

WF

WB

CDX

Left-hand shown

Designation CW CDX (1) H HF B OAL WB WF HBH LH Insert

THDR 3232-17T38 17.00 38.00 32.0 32.0 32.0 170.00 16.00 24.00 8.0 50.0 TIGERV 1740 SR 14-519 BLD T20/M7 SW6-T

THDR/L 4040-17T45 17.00 45.00 40.0 40.0 40.0 170.00 15.00 32.50 - - TIGERV 1740 SR 14-519 BLD T20/M7 SW6-T

THDR/L 3232-20T38 20.06 38.00 32.0 32.0 32.0 170.00 17.50 23.30 8.0 50.0 TIGERV 2006 SR 14-519 BLD T20/M7 SW6-T

THDN 3232-20T38 20.06 38.00 32.0 32.0 32.0 170.00 17.50 16.00 8.0 50.0 TIGERV 2006 SR 14-519 BLD T20/M7 SW6-T

THDR/L 4040-20T45 20.06 45.00 40.0 40.0 40.0 170.00 17.50 31.30 - - TIGERV 2006 SR 14-519 BLD T20/M7 SW6-T

THDN 4040-20T45 20.06 45.00 40.0 40.0 40.0 170.00 17.50 20.00 - - TIGERV 2006 SR 14-519 BLD T20/M7 SW6-T

• For grooving only

(1) Cutting depth maximum

For inserts, see pages: TIGERV (334)

TIGERV

Utility Single-Ended Inserts

for External Deep Grooving CW

and Heavy Machining

RE 6.5

Y Chipformer CW Chipformer

Recommended

Dimensions Tough 1 Hard

Machining Data

IC830 IC808 f groove

Designation CW RE CWTOL (1) RETOL (2) IC20 (mm/rev)

TIGERV 1700-200-CW 17.00 2.00 0.08 0.050 • 0.20-0.60

TIGERV 2006-152 20.06 1.52 0.08 0.050 • • • 0.30-0.60

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: THDR/L/N (334)

334 ISCAR