Page 428 - ISCAR(TURNING-CATALOG-42-2022)

P. 428

USER GUIDE

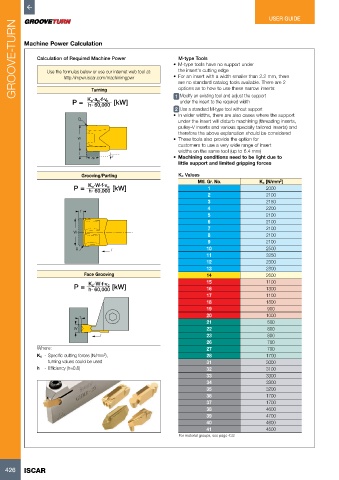

GROOVE-TURN Machine Power Calculation • M-type tools have no support under

Calculation of Required Machine Power

M-type Tools

the insert’s cutting edge

Use the formulas below or use our internet web tool at:

• For an insert with a width smaller than 2.2 mm, there

http://mpwr.iscar.com/machinimgpwr

are no standard catalog tools available. There are 2

options as to how to use these narrow inserts:

Turning

P = K ∙a ∙f∙v c [kW] 1 Modify an existing tool and adjust the support

p

c

under the insert to the required width

h∙ 60,000

2 Use a standard M-type tool without support

• In wider widths, there are also cases where the support

R under the insert will disturb machining (threading inserts,

pulley-V inserts and various specially tailored inserts) and

therefore the above explanation should be considered

W • These tools also provide the option for

customers to use a very wide range of insert

widths on the same tool (up to 6.4 mm)

f

ap f • Machining conditions need to be light due to

little support and limited gripping forces

Grooving/Parting Kc Values

Mtl. Gr. No. Kc [N/mm ]

2

K ∙W∙f∙v

c

P = h∙ 60,000 [kW] 1 2000

c

2 2100

3 2150

4 2200

f

5 2100

6 2100

7 2100

W

8 2100

9 2100

R f 10 2500

11 3250

12

2300

TEXT Face Grooving 13 2800

14

2600

c

P = K ∙W∙f∙v c [kW] 15 1100

16

1300

h∙ 60,000

17 1100

18 1800

19 900

20 1000

f

21 500

W 22 800

f 23 800

26 700

Where: 27 700

Kc - Specific cutting forces (N/mm ), 28 1700

2

turning values could be used 31 3000

h - Efficiency (h≈0.8) 32 3100

33 3300

34 3300

35 3200

36 1700

37 1700

38 4600

39 4700

40 4600

41 4500

For material groups, see page 432

426 ISCAR