Page 423 - ISCAR(TURNING-CATALOG-42-2022)

P. 423

USER GUIDE

Machining Tips

Insert Width Insert Radius GROOVE-TURN

Generally, the insert width should be as wide as Choosing the insert radius for a particular application is a

possible as it contributes to its strength. However, combination of many factors.

there are additional considerations that should be taken The corner radius of the groove-turn insert

into account in order to choose the correct width: influences the product shape and tool life.

• Workpiece size and clamping stability: A larger • A larger radius in turning operations

width means higher cutting forces during normally improves surface quality.

grooving. A width that is too large can cause • An insert with a larger radius has a better distribution

deformation of the workpiece and/or vibration. of the cutting load and of the generated heat.

• When using a larger width, make sure your It is stronger and ensures longer tool life.

machine has enough power. (see page 426) • Small radii on grip inserts result in increased side

• Machining strategy: Grooving in a correct sequence forces and side deflection, preventing instability,

should also affect your choice. (see page 422) especially with small depths of cut and feed.

• Required overhang: A larger tool overhang will • The best radius to use is basically determined by

require a wider insert to maintain stability. the geometry and dimensions of the workpiece.

• The larger the insert, the wider the upper and The more securely the workpiece is fastened in

lower jaws can be, therefore, higher forces are the machine tool, the larger the radius may be.

required to effect the necessary side deflection. • When the ratio of a workpiece’s length

• If the depth of cut is small, the width of the compared to its diameter is large, inserts

insert should be proportionately smaller to with smaller radii will prevent chatter.

guarantee the required deflection. • A larger corner radius enables

machining at a larger feed rate.

• In profiling operations, inserts with larger

corner radii or full radii are required.

TEXT

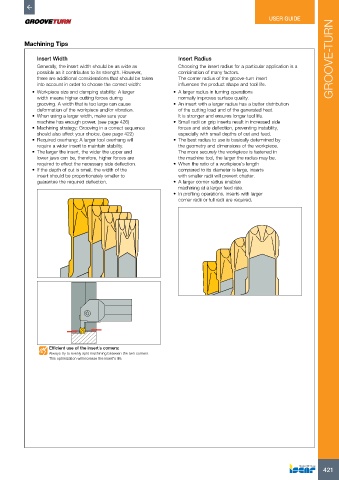

Efficient use of the insert’s corners:

Always try to evenly split machining between the two corners.

This optimization will increase the insert’s life.

421