Page 438 - ISCAR(TURNING-CATALOG-42-2022)

P. 438

USER GUIDE

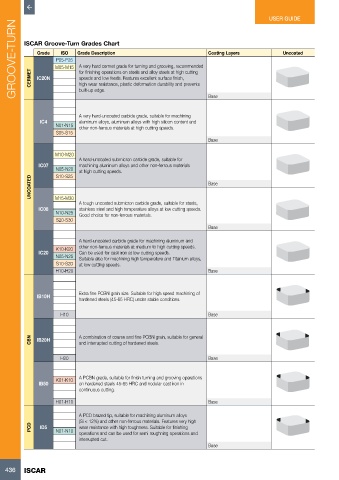

GROOVE-TURN ISCAR Groove-Turn Grades Chart Coating Layers Uncoated

Grade

Grade Description

ISO

P05-P25

A very hard cermet grade for turning and grooving, recommended

M05-M15

for finishing operations on steels and alloy steels at high cutting

CERMET

IC20N

speeds and low feeds. Features excellent surface finish,

high wear resistance, plastic deformation durability and prevents

built-up edge.

A very hard-uncoated carbide grade, suitable for machining Base

IC4 aluminum alloys, aluminum alloys with high silicon content and

N01-N15 other non-ferrous materials at high cutting speeds.

S05-S15

Base

M10-M20

A hard-uncoated submicron carbide grade, suitable for

IC07 machining aluminum alloys and other non-ferrous materials

N05-N20 at high cutting speeds.

S10-S25

UNCOATED Base

M15-M30

A tough uncoated submicron carbide grade, suitable for steels,

IC08 stainless steel and high temperature alloys at low cutting speeds.

N10-N25 Good choice for non-ferrous materials.

S20-S30

Base

A hard-uncoated carbide grade for machining aluminum and

K10-K20 other non-ferrous materials at medium to high cutting speeds.

IC20 Can be used for cast iron at low cutting speeds.

N05-N25 Suitable also for machining high temperature and Titanium alloys,

TEXT H10-H20 at low cutting speeds. Base

S10-S20

Extra fine PCBN grain size. Suitable for high speed machining of

IB10H

hardened steels (45-65 HRC) under stable conditions.

H10 Base

CBN IB20H A combination of coarse and fine PCBN grain, suitable for general

and interrupted cutting of hardened steels.

H20 Base

K01-K10 A PCBN grade, suitable for finish turning and grooving operations

IB50 on hardened steels 45-65 HRC and nodular cast iron in

continuous cutting.

H01-H10 Base

A PCD brazed tip, suitable for machining aluminum alloys

(Si < 12%) and other non-ferrous materials. Features very high

PCD ID5 N01-N10 wear resistance with high toughness. Suitable for finishing

operations and can be used for semi roughning operations and

interrupted cut.

Base

436 ISCAR