Page 443 - ISCAR(TURNING-CATALOG-42-2022)

P. 443

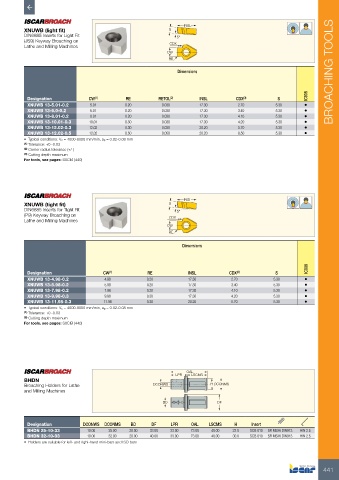

XNUWB (light fit) S INSL

DIN6885 Inserts for Light Fit 5°

(JS9) Keyway Broaching on

Lathe and Milling Machines CDX

CW

RE

Dimensions BROACHING TOOLS

IC908

Designation CW (1) RE RETOL (2) INSL CDX (3) S

XNUWB 13-5.01-0.2 5.01 0.20 0.030 17.30 2.70 5.30 •

XNUWB 13-6.0-0.2 6.01 0.20 0.030 17.30 3.40 5.30 •

XNUWB 13-8.01-0.2 8.01 0.20 0.030 17.30 4.10 5.30 •

XNUWB 13-10.01-0.3 10.01 0.30 0.030 17.30 4.20 5.30 •

XNUWB 13-12.02-0.3 12.02 0.30 0.030 20.20 5.70 5.30 •

XNUWB 13-12.02-0.5 12.02 0.50 0.050 20.20 8.50 5.30 •

• Typical conditions: Vc = 4000-8000 mm/min, ap = 0.02-0.08 mm

(1) Tolerance: +0 -0.03

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: SXCIB (440)

INSL

XNUWB (tight fit) S

DIN6885 Inserts for Tight Fit 5°

(P9) Keyway Broaching on CDX

Lathe and Milling Machines

CW

RE

Dimensions

IC908

Designation CW (1) RE INSL CDX (2) S

XNUWB 13-4.98-0.2 4.98 0.20 17.30 2.70 5.30 •

XNUWB 13-5.98-0.2 5.98 0.20 17.30 3.40 5.30 •

XNUWB 13-7.98-0.2 7.98 0.20 17.30 4.10 5.30 •

XNUWB 13-9.98-0.3 9.98 0.30 17.30 4.20 5.30 •

XNUWB 13-11.98-0.3 11.98 0.30 20.20 5.70 5.30 •

• Typical conditions: Vc = 4000-8000 mm/min, ap = 0.02-0.08 mm

(1) Tolerance: +0 -0.03

(2) Cutting depth maximum

For tools, see pages: SXCIB (440)

LPR OAL LSCMS

BHDN

Broaching Holders for Lathe DCONWS H DCONMS

and Milling Machines

BD DF

Designation DCONWS DCONMS BD DF LPR OAL LSCMS H Insert

BHDN 25-10-33 10.00 25.00 20.00 33.00 33.00 73.00 40.00 23.0 SCB 010 SR M5X6 DIN913 HW 2.5

BHDN 32-10-33 10.00 32.00 20.00 40.00 33.00 73.00 40.00 30.0 SCB 010 SR M5X6 DIN913 HW 2.5

• Holders are suitable for left- and right-hand mini-bars and ISO bars

441