Page 471 - ISCAR(TURNING-CATALOG-42-2022)

P. 471

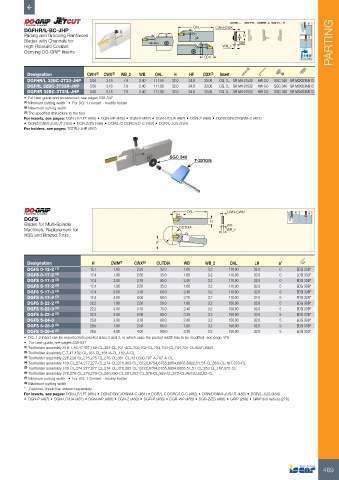

DGHFL... DGHFR... DGHFR...L DGHFL...R

DGFHR/L-BC-JHP OAL CWN-CWX

Parting and Grooving Reinforced HF H

Blades with Channels for MinMax WB PARTING

High-Pressure Coolant WB_2

Carrying DO-GRIP Inserts

CDX Bar Max

Designation CWN (1) CWX (2) WB_2 WB OAL H HF CDX (3) Insert

DGFHR/L 32BC-3T33-JHP 3.00 3.18 7.9 2.40 111.00 32.0 24.8 33.00 DG. 3.. SR M4-21532 HW 3.0 SGC 340 SR M3X3DIN913

DGFHL 32BC-3T33R-JHP 3.00 3.18 7.9 2.40 111.00 32.0 24.8 33.00 DG. 3.. SR M4-21532 HW 3.0 SGC 340 SR M3X3DIN913

DGFHR 32BC-3T33L-JHP 3.00 3.18 7.9 2.40 111.00 32.0 24.8 33.00 DG. 3.. SR M4-21532 HW 3.0 SGC 340 SR M3X3DIN913

• For user guide and accessories, see pages 538-547

(1) Minimum cutting width • For DG: 1.0 insert - modify holder

(2) Maximum cutting width

(3) The specified limit refers to the tool

For inserts, see pages: DGN-LF/LFT (485) • DGN-MF (485) • DGN-P (487) • DGN-UT/UA (487) • DGN-Z (486) • DGN/DGNC/DGNM-C (481)

• DGN/DGNM-J/JS/JT (483) • DGR-Z/ZS (486) • DGR/L-C DGRC/LC-C (482) • DGR/L-J/JS (484)

For holders, see pages: TGTBU-JHP (497)

SGC 340

T-2010/5

OAL CWN-CWN

DGFS LH H

Blades for Multi-Spindle WB

Machines, Replacement for CUTDIA WB_2

HSS and Brazed Tools

a°

Designation H CWN (7) CWX (8) CUTDIA WB WB_2 OAL LH a°

DGFS 0-12-2 (1) 12.7 1.90 2.50 32.0 1.60 3.2 110.00 32.0 0 EDG 33B*

DGFS 0-17-2 (2) 17.4 1.90 2.50 35.0 1.60 3.2 110.00 32.0 0 EDG 33B*

DGFS 0-17-3 (2) 17.4 3.00 3.18 60.0 2.40 3.2 110.00 32.0 0 EDG 33B*

DGFS 5-17-2 (3) 17.4 1.90 2.50 35.0 1.60 3.2 110.00 32.0 5 EDG 33B*

DGFS 5-17-3 (3) 17.4 3.00 3.18 60.0 2.40 3.2 110.00 32.0 5 EDG 33B*

DGFS 5-17-4 (3) 17.4 4.00 4.00 60.0 3.20 3.2 110.00 32.0 5 EDG 33B*

DGFS 5-22-2 (4) 22.2 1.90 2.50 50.0 1.60 3.2 150.00 32.0 5 EDG 33B*

DGFS 5-22-3 (5) 22.2 3.00 3.18 75.0 2.40 3.2 150.00 32.0 5 EDG 33B*

DGFS 5-22-4 (5) 22.2 4.00 4.00 80.0 3.20 3.2 150.00 32.0 5 EDG 33B*

DGFS 5-24-3 23.8 3.00 3.18 80.0 2.40 3.2 150.00 32.0 5 EDG 33B*

DGFS 5-28-2 (6) 28.5 1.90 2.50 65.0 1.60 3.2 150.00 32.0 5 EDG 33B*

DGFS 5-28-4 (6) 28.5 4.00 4.00 100.0 3.20 3.2 150.00 32.0 5 EDG 33B*

• DG..1.0 insert can be mounted into pocket sizes 2 and 3. in which case the pocket width has to be modified -see page 479

• For user guide, see pages 538-547

(1) Toolholder assembly X18-1,46,47-WT,160-CL,354-CL,701-ACL,702,702-CL,703,703-CL,704,704-CL,6921,6925

(2) Toolholder assembly E-7,47,102-CL,103-CL,161-A-CL,162-A-CL

(3) Toolholder assembly 226,226-CL,275,275-CL,276-CL,361-CL,431,630,707-A,707-A-CL

(4) Toolholder assembly 100-CL,274,277,277-CL,274-CL,370,383-CL, 6722,6754,6755,6854,6855,6922,51,51-CL,353-CL,167,370-CL

(5) Toolholder assembly 100-CL,274,277,277-CL,274-CL,370,383-CL, 6722,6754,6755,6854,6855,51,51-CL,353-CL,167,370-CL

(6) Toolholder assembly 278,278-CL,279,279-CL,280,280-CL,281,281-CL,375-CL,359-CL,372-CL,A6120,52,52-CL

(7) Minimum cutting width • For DG: 1.0 insert - modify holder

(8) Maximum cutting width

* Optional, should be ordered separately

For inserts, see pages: DGN-LF/LFT (485) • DGN/DGNC/DGNM-C (481) • DGR/L-C DGRC/LC-C (482) • DGN/DGNM-J/JS/JT (483) • DGR/L-J/JS (484)

• DGN-P (487) • DGN-UT/UA (487) • DGN-WP (488) • DGN-Z (486) • DGR-P (488) • DGR-WP (488) • DGR-Z/ZS (486) • GRIP (269) • GRIP (full radius) (270)

469