Page 475 - ISCAR(TURNING-CATALOG-42-2022)

P. 475

CNT (typ.x3)

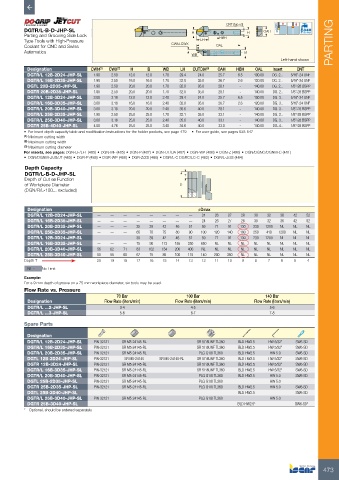

DGTR/L-B-D-JHP-SL H H OAH

Parting and Grooving Side Lock HBH Bar Max

Type Tools with High-Pressure LH PARTING

Coolant for CNC and Swiss CWN-CWX OAL

Automatics B

WB

Left-hand shown

Designation CWN (1) CWX (2) H B WB LH CUTDIA (3) OAH HBH OAL Insert CNT

DGTR/L 12B-2D24-JHP-SL 1.90 2.50 12.0 12.0 1.70 29.4 24.0 25.7 6.5 100.00 DG. 2... 5/16"-24 UNF

DGTR/L 16B-2D35-JHP-SL 1.90 2.50 16.0 16.0 1.70 32.0 35.0 26.7 2.6 120.00 DG. 2... 5/16"-24 UNF

DGTL 20B-2D35-JHP-SL 1.90 2.50 20.0 20.0 1.70 32.0 35.0 28.1 - 140.00 DG. 2... 1/8"-28 BSPP

DGTR 20B-2D35-JHP-SL 1.90 2.50 20.0 20.0 1.70 32.0 35.0 28.1 - 140.00 DG. 2.. 1/8"-28 BSPP

DGTR/L 12B-3D24-JHP-SL 3.00 3.18 12.0 12.0 2.40 29.4 24.0 25.7 6.5 100.00 DG. 3.. 5/16"-24 UNF

DGTR/L 16B-3D35-JHP-SL 3.00 3.18 16.0 16.0 2.40 32.0 35.0 26.7 2.6 120.00 DG. 3.. 5/16"-24 UNF

DGTR/L 20B-3D40-JHP-SL 3.00 3.18 20.0 20.0 2.40 35.6 40.0 28.1 - 140.00 DG. 3.. 1/8"-28 BSPP

DGTR/L 25B-2D35-JHP-SL 1.90 2.50 25.0 25.0 1.70 32.1 35.0 33.1 - 140.00 DG. 2.. 1/8"-28 BSPP

DGTR/L 25B-3D40-JHP-SL 3.00 3.18 25.0 25.0 2.40 35.6 40.0 33.1 - 140.00 DG. 3.. 1/8"-28 BSPP

DGTR 25B-4D40-JHP-SL 4.00 4.76 25.0 25.0 3.40 34.6 40.0 33.0 - 140.00 DG..4.. 1/8"-28 BSPP

• For insert depth capacity table and modification instructions for the holder pockets, see page 479 • For user guide, see pages 538-547

(1) Minimum cutting width

(2) Maximum cutting width

(3) Maximum cutting diameter

For inserts, see pages: DGN-LF/LFT (485) • DGN-MF (485) • DGN-P (487) • DGN-UT/UA (487) • DGN-WP (488) • DGN-Z (486) • DGN/DGNC/DGNM-C (481)

• DGN/DGNM-J/JS/JT (483) • DGR-P (488) • DGR-WP (488) • DGR-Z/ZS (486) • DGR/L-C DGRC/LC-C (482) • DGR/L-J/JS (484)

Depth Capacity

DGTR/L-B-D-JHP-SL T

Depth of Cut as Function

of Workpiece Diameter D

(DGN/R/L-100... excluded)

Designation øDmax

DGTR/L 12B-2D24-JHP-SL — — — — — — — — 24 26 27 28 30 32 36 42 52

DGTR/L 16B-2D35-JHP-SL — — — — — — — — 24 26 27 28 30 32 36 42 52

DGTR/L 20B-2D35-JHP-SL — — — 35 39 42 46 51 59 71 91 130 230 1200 NL NL NL

DGTR/L 25B-2D35-JHP-SL — — — 65 70 75 80 90 100 120 140 180 250 410 1200 NL NL

DGTR/L 12B-3D24-JHP-SL — — — 35 39 42 46 51 59 71 91 130 230 1200 NL NL NL

DGTR/L 16B-3D35-JHP-SL — — — 75 90 113 155 250 650 NL NL NL NL NL NL NL NL

DGTR/L 20B-3D40-JHP-SL 56 62 71 83 102 134 200 400 NL NL NL NL NL NL NL NL NL

DGTR/L 25B-3D40-JHP-SL 50 55 60 67 75 85 100 115 140 200 350 NL NL NL NL NL NL

Depth T 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4

NL - No Limit

Example:

For a 9 mm depth of groove on a 75 mm workpiece diameter, six tools may be used.

Flow Rate vs. Pressure

70 Bar 100 Bar 140 Bar

Designation Flow Rate (liters/min) Flow Rate (liters/min) Flow Rate (liters/min)

DGTR/L ...2-JHP-SL 3-4 4-5 5-6

DGTR/L ...3-JHP-SL 5-6 6-7 7-8

Spare Parts

Designation

DGTR/L 12B-2D24-JHP-SL PIN-32121 SR M5-24145-RL SR 5/16UNF TL360 BLD HW2.5 HW 5/32" SW6-SD

DGTR/L 16B-2D35-JHP-SL PIN-32121 SR M5-24145-RL SR 5/16UNF TL360 BLD HW2.5 HW 5/32" SW6-SD

DGTR/L 20B-2D35-JHP-SL PIN-32121 SR M5-24145-RL PLG G1/8 TL360 BLD HW2.5 HW 5.0 SW6-SD

DGTL 12B-3D24-JHP-SL PIN-32121 SR M5-24145 SR M5-24145-RL SR 5/16UNF TL360 BLD HW2.5 HW 5/32" SW6-SD

DGTR 12B-3D24-JHP-SL PIN-32121 SR M5-24145-RL SR 5/16UNF TL360 BLD HW2.5 HW 5/32" SW6-SD

DGTR/L 16B-3D35-JHP-SL PIN-32121 SR M5-24145-RL SR 5/16UNF TL360 BLD HW2.5 HW 5/32" SW6-SD

DGTR/L 20B-3D40-JHP-SL PIN-32121 SR M5-24145-RL PLG G1/8 TL360 BLD HW2.5 HW 5.0 SW6-SD

DGTL 25B-2D35-JHP-SL PIN-32121 SR M5-24145-RL PLG G1/8 TL360 HW 5.0

DGTR 25B-2D35-JHP-SL PIN-32121 SR M5-24145-RL PLG G1/8 TL360 BLD HW2.5 HW 5.0 SW6-SD

DGTL 25B-3D40-JHP-SL BLD HW2.5 SW6-SD

DGTR/L 25B-3D40-JHP-SL PIN-32121 SR M5-24145-RL PLG G1/8 TL360 HW 5.0

DGTR 25B-3D40-JHP-SL BLD HW2.5* SW6-SD*

* Optional, should be ordered separately

473