Page 609 - ISCAR(TURNING-CATALOG-42-2022)

P. 609

USER GUIDE

FACE GROOVING

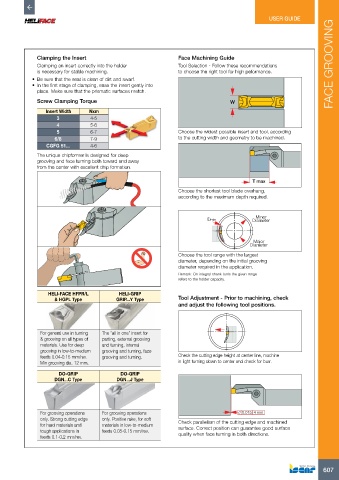

Clamping the Insert Face Machining Guide

Clamping an insert correctly into the holder Tool Selection - Follow these recommendations

is necessary for stable machining. to choose the right tool for high peformance.

• Be sure that the seat is clean of dirt and swarf.

• In the first stage of clamping, ease the insert gently into

place. Make sure that the prismatic surfaces match.

Screw Clamping Torque W

Insert Width Nxm

3 4-5

4 5-6

5 6-7 Choose the widest possible insert and tool, according

6/8 7-9 to the cutting width and geometry to be machined.

CGFG 51... 4-6

The unique chipformer is designed for deep

grooving and face turning both toward and away

from the center with excellent chip formation.

T max

Choose the shortest tool blade overhang,

according to the maximum depth required.

Minor

Dmin Diameter

Major

Diameter

Choose the tool range with the largest

diameter, depending on the initial grooving

diameter required in the application.

Remark: On integral shank tools the given range

refers to the holder capacity.

HELI-FACE HFPR/L HELI-GRIP

& HGPL Type GRIP...Y Type Tool Adjustment - Prior to machining, check

and adjust the following tool positions.

For general use in turning The “all in one” insert for

& grooving on all types of parting, external grooving

materials. Use for deep and turning, internal

grooving in low-to-medium grooving and turning, face

feeds 0.04-0.15 mm/rev. grooving and turning. Check the cutting edge height at center line, machine

Min grooving dia. 12 mm. in light turning down to center and check for burr.

DO-GRIP DO-GRIP

DGN...C Type DGN...J Type

For grooving operations For grooving operations // 0.015 4 mm

only. Strong cutting edge only. Positive rake, for soft

for hard materials and materials in low-to-medium Check parallelism of the cutting edge and machined

surface. Correct position can guarantee good surface

tough applications in feeds 0.05-0.15 mm/rev.

feeds 0.1-0.2 mm/rev. quality when face turning in both directions.

607