Page 729 - ISCAR(TURNING-CATALOG-42-2022)

P. 729

USER GUIDE

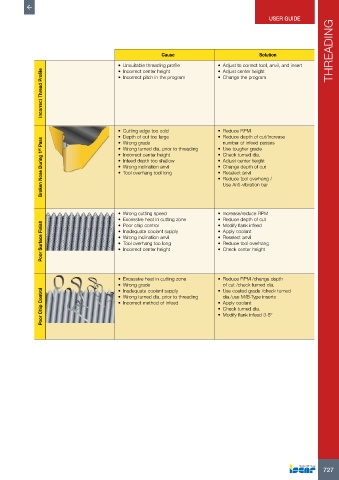

THREADING

Cause Solution

• Unsuitable threading profile • Adjust to correct tool, anvil, and insert

• Adjust center height

• Incorrect center height

Incorrect Thread Profile

• Change the program

• Incorrect pitch in the program

• Cutting edge too cold • Reduce RPM

• Depth of cut too large • Reduce depth of cut/Increase

Broken Nose During 1 st Pass • Incorrect center height • Check turned dia.

• Wrong grade

number of infeed passes

• Use tougher grade

• Wrong turned dia. prior to threading

• Adjust center height

• Infeed depth too shallow

• Change depth of cut

• Wrong inclination anvil

• Reselect anvil

• Tool overhang tool long

• Reduce tool overhang /

Use Anti-vibration bar

• Wrong cutting speed • Increase/reduce RPM

• Excessive heat in cutting zone • Reduce depth of cut

Poor Surface Finish • Inadequate coolant supply • Apply coolant

• Modify flank infeed

• Poor chip control

• Wrong inclination anvil

• Reselect anvil

• Reduce tool overhang

• Tool overhang too long

• Check center height

• Incorrect center height

• Excessive heat in cutting zone • Reduce RPM /change depth

of cut /check turned dia.

• Wrong grade • Use coated grade /check turned

Poor Chip Control • Wrong turned dia. prior to threading • Apply coolant

• Inadequate coolant supply

dia./use M/B-Type inserts

• Incorrect method of infeed

• Check turned dia.

• Modify flank infeed 3-5°

727