Page 435 - DC_SWISS(Catalogue_TM_ES-EN)

P. 435

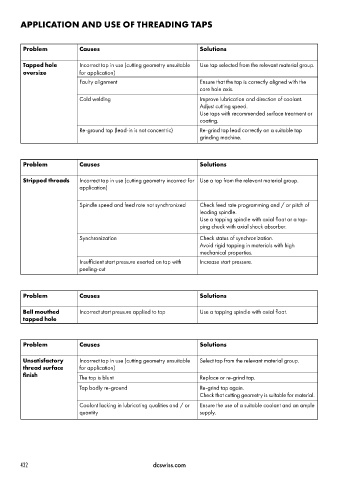

APPLICATION AND USE OF THREADING TAPS

Problem Causes Solutions

Tapped hole Incorrect tap in use (cutting geometry unsuitable Use tap selected from the relevant material group.

oversize for application)

Faulty alignment Ensure that the tap is correctly aligned with the

core hole axis.

Cold welding Improve lubrication and direction of coolant.

Adjust cutting speed.

Use taps with recommended surface treatment or

coating.

Re-ground tap (lead-in is not concentric) Re-grind tap lead correctly on a suitable tap

grinding machine.

Problem Causes Solutions

Stripped threads Incorrect tap in use (cutting geometry incorrect for Use a tap from the relevant material group.

application)

Spindle speed and feed rate not synchronized Check feed rate programming and / or pitch of

leading spindle.

Use a tapping spindle with axial float or a tap-

ping chuck with axial shock absorber.

Synchronization Check status of synchronization.

Avoid rigid tapping in materials with high

mechanical properties.

Insufficient start pressure exerted on tap with Increase start pressure.

peeling-cut

Problem Causes Solutions

Bell mouthed Incorrect start pressure applied to tap Use a tapping spindle with axial float.

tapped hole

Problem Causes Solutions

Unsatisfactory Incorrect tap in use (cutting geometry unsuitable Select tap from the relevant material group.

thread surface for application)

finish The tap is blunt Replace or re-grind tap.

Tap badly re-ground Re-grind tap again.

Check that cutting geometry is suitable for material.

Coolant lacking in lubricating qualities and / or Ensure the use of a suitable coolant and an ample

quantity supply.

432 dcswiss.com